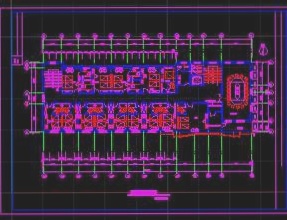

1. The placement of components on a printed circuit board (PCB) may appear random at first glance, but in the design phase, several considerations must be taken into account. This involves a comprehensive assessment of data signals, aesthetics, durability, and heat management.

2. Signal interference within PCB circuitry stands as the foremost challenge during component placement. It is imperative to separate or isolate weak and strong data signal power supply circuits. Additionally, high-frequency components should be segregated from low-frequency ones, and communication components should be distinct from those handling alternating current. Attention to detail is crucial, including the orientation of power cords, layout of grounding lines, and implementation of appropriate shielding and filtering measures.

3. For electronic devices generating significant heat, priority lies in ensuring adequate thermal dissipation. Only after establishing an optimal thermal environment should placement be determined. Particularly in precision PCB manufacturing, potential temperature impacts on sensitive components, such as power circuits, must be carefully considered. The process of surface mounting involves exposure to various external forces and vibrations, necessitating a scientific approach to board layout and hole placement to mitigate potential damage.

4. Aesthetic considerations also play a vital role in PCB design. The appearance of the board is often the first aspect evaluated during project acceptance by customers. Hence, it is essential to prioritize an aesthetically pleasing layout.

5. PCBs have become integral to daily life, influencing various facets of technology. Continued emphasis on brand enhancement features is crucial to gradually enhance the user experience of terminal equipment. Qixiang Electronic Devices, with eight years of dedicated experience in PCB manufacturing, places quality at the forefront. Their primary product offerings include front and back PCB circuit boards, solid wood multilayer boards, and components such as Type-C connectors, RJ-45 ports, and solar cells, catering to devices ranging from smartphones and computers to medical equipment and intelligent robotics.

2. Signal interference within PCB circuitry stands as the foremost challenge during component placement. It is imperative to separate or isolate weak and strong data signal power supply circuits. Additionally, high-frequency components should be segregated from low-frequency ones, and communication components should be distinct from those handling alternating current. Attention to detail is crucial, including the orientation of power cords, layout of grounding lines, and implementation of appropriate shielding and filtering measures.

3. For electronic devices generating significant heat, priority lies in ensuring adequate thermal dissipation. Only after establishing an optimal thermal environment should placement be determined. Particularly in precision PCB manufacturing, potential temperature impacts on sensitive components, such as power circuits, must be carefully considered. The process of surface mounting involves exposure to various external forces and vibrations, necessitating a scientific approach to board layout and hole placement to mitigate potential damage.

4. Aesthetic considerations also play a vital role in PCB design. The appearance of the board is often the first aspect evaluated during project acceptance by customers. Hence, it is essential to prioritize an aesthetically pleasing layout.

5. PCBs have become integral to daily life, influencing various facets of technology. Continued emphasis on brand enhancement features is crucial to gradually enhance the user experience of terminal equipment. Qixiang Electronic Devices, with eight years of dedicated experience in PCB manufacturing, places quality at the forefront. Their primary product offerings include front and back PCB circuit boards, solid wood multilayer boards, and components such as Type-C connectors, RJ-45 ports, and solar cells, catering to devices ranging from smartphones and computers to medical equipment and intelligent robotics.