PCB Production and Advancements in Technology

PCB production involves various procedures and materials, with LED PCB manufacturers prioritizing safety measures. Adhering to production principles is crucial when handling printed circuit boards.

Advancements in technology have led to the development of advanced PCBs that efficiently connect electronic components in a cost-effective manner. These PCBs are constructed with protective materials and a metal-covered surface, featuring engravings to ensure seamless coordination among parts. Components are welded onto the surface to complete the project, offering numerous advantages and making them essential in electronic devices.

Flexibility and Versatility of PCBs

Due to their flexibility, PCBs can accommodate compact electronic circuits, commonly used in computers and motherboards. With additional holes and drill bits, PCBs can support various components like capacitors. Whether running a small or large PCB business, having a reliable supplier is crucial for obtaining materials at competitive prices.

Utilization of PCB Prototypes

Companies and electronic brands widely utilize PCB prototypes due to the high volume of orders typically required. These prototypes serve as initial models for testing, confirming the functionality and preferences of the final product.

WellCircuits Limited: Specialized PCB Manufacturer

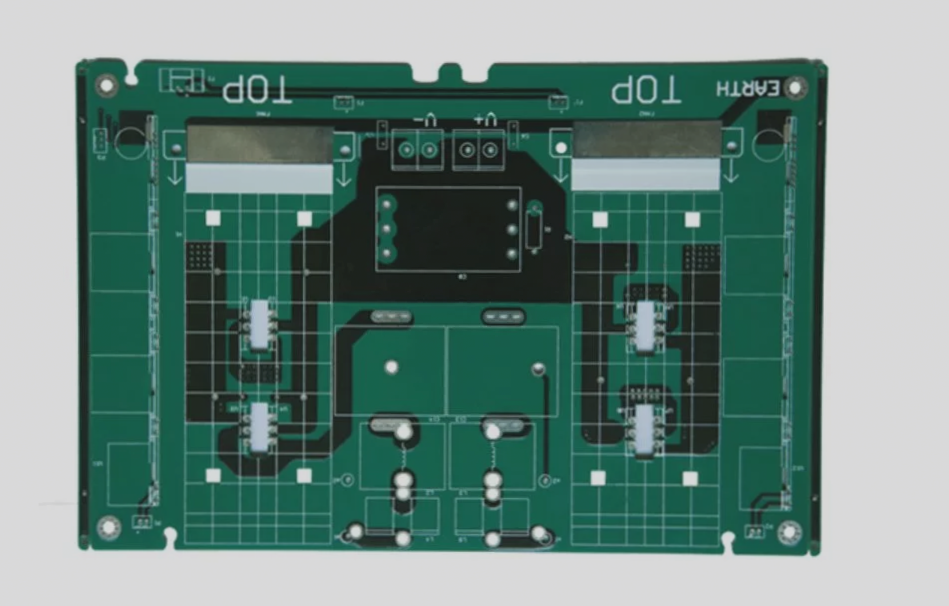

WellCircuits Limited specializes in manufacturing high-precision double-sided, multi-sided, impedance, blind buried vias, and thick copper circuit boards. Their product range includes HDI, thick copper, backplanes, rigid-flex combinations, buried capacitance and resistance, golden finger, and other circuit boards to meet diverse customer needs.