When planning to build a printed circuit board (PCB) from a manufacturer, one essential component you will encounter is the bill of materials, commonly referred to as the BOM. So, what exactly does this list of materials entail? What factors does it include? As you read this article, do any of these questions come to mind? While it’s not rocket science, it’s certainly helpful to grasp. The following post clarifies the concept of the BOM and outlines the key considerations for preparing a bill of materials file. Keep reading to learn more.

What is a bill of materials?

—

Let me know if you need any further changes!

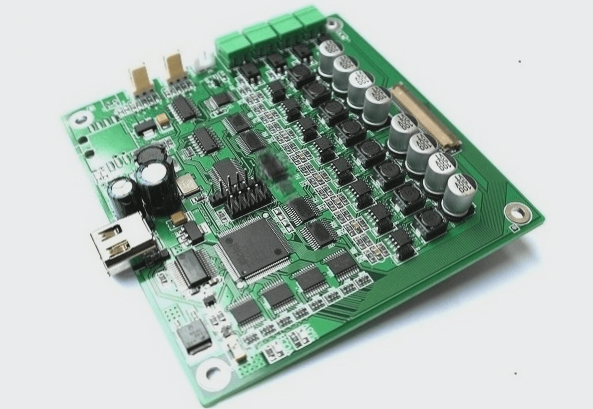

1. The bill of materials is essentially a document that encompasses all the necessary information for assembling a printed circuit board (PCB). It is one of the most crucial elements required during PCB manufacturing. Failing to provide a list of materials can lead to significant confusion. This, in turn, may result in complications and unnecessary modifications during assembly, causing delays. To avoid such issues, it’s always advisable to furnish a well-prepared BOM. You might wonder what specific details are included in the list of materials. This leads us to the next section.

2. What is included in the bill of materials?

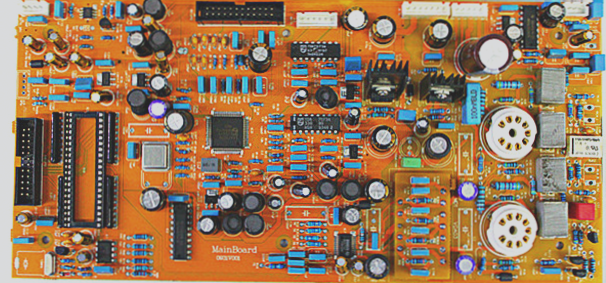

Now that we understand what a bill of materials is, let’s explore the key information that should be included:

3. Manufacturer’s name: It’s beneficial to specify the manufacturer’s name and preferably use its parts and components for assembly. Additionally, listing alternative manufacturers is advisable. This can save considerable time in the event that components from major manufacturers are unavailable.

4. Manufacturer’s part number: Each component distributor assigns a unique identification number to their parts. Providing these accurate part numbers to the manufacturer ensures the procurement of the exact components needed.

5. Part description: Following the manufacturer’s name and part number, it’s essential to include detailed specifications. This aids manufacturers in understanding the precise application requirements and determining the appropriate components for PCB design and manufacturing.

6. Component value: Specifying the value of the components to be used (such as resistance and capacitance) is crucial. This assists the assembly service provider in sourcing components with the correct required values.

7. Product quantity: It’s important to avoid ordering excessive products or experiencing shortages. This can lead to increased costs or delays. Therefore, providing an accurate quantity list is vital.

8. Reference number: The reference number provides essential information to pinpoint the exact location of components on the printed circuit board.

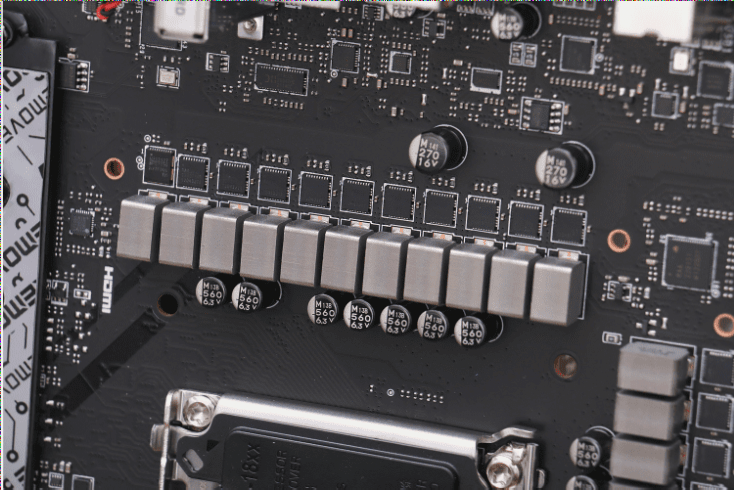

9. Placement method: The placement method refers to the technique used to mount parts and components on a PCB, which can be through-hole or surface mount technology (SMT). This information enables the manufacturer to implement the selected method appropriately.

10. These are the key elements that should never be overlooked when preparing a bill of materials for the design, manufacturing, and placement of printed circuit boards.