The Latest Advancements in PCB Copper Clad Laminate Technology

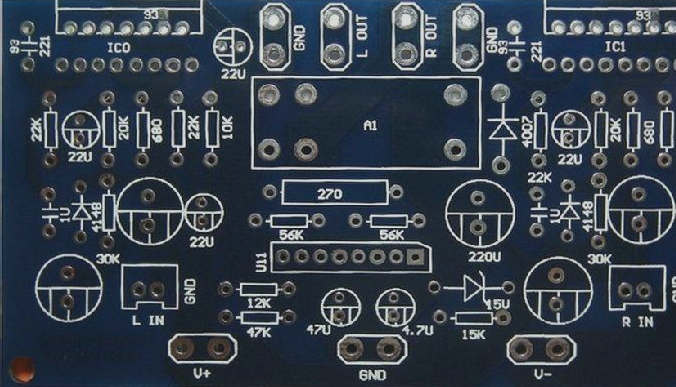

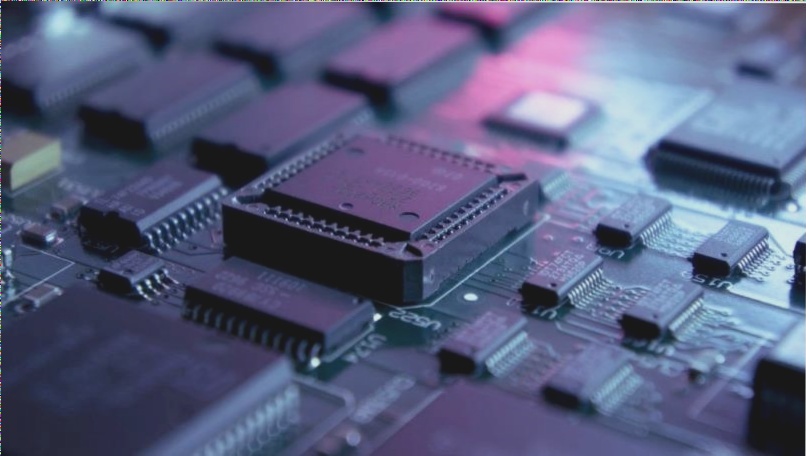

The PCB circuit diagram template is created on film, and the exposure, development, and etching machines used have all been fully localized. The core technology of PCB production revolves around copper-clad laminate technology, and domestic advancements in this area are now comparable to international standards.

General Production Process of Copper Clad Laminate:

- Prepare a solution of resin, filler, and organic solvents (primarily acetone and methyl ethyl ketone) – soak the glass fiber cloth in the resin solution, then dry it. The dried glass fiber cloth is referred to as PP sheet in the industry. Based on the required thickness of the copper-clad laminate, stack the PP sheets and place copper foil on both the top and bottom surfaces. Align them carefully, then place the stack in a constant temperature and pressure press for pressing and curing. The material is removed once the preset curing time is completed.

Characteristics of Copper Clad Laminate:

- High temperature resistance, meaning the glass transition temperature (Tg) should be elevated, ensuring it does not soften easily.

- Strong peel strength of the copper foil on the laminate, making it resistant to tearing.

- High flame resistance, good breakdown voltage, and a stable dielectric constant.

Core Technology of Copper Clad Laminate

Key Factors in Copper Clad Laminate Technology:

- One key factor is the resin, filler, and curing agent used. Among these, resin is the most critical.

- The second key factor is the laminated combination technology, which can be understood as: within the copper clad laminate, there exists another layer of copper clad laminate.

- The most commonly used resin in the industry is bisphenol A epoxy resin. If higher temperature resistance is required for the copper clad laminate, such as a higher Tg (glass transition temperature), phenolic resin or modified bisphenol A epoxy resin can be used.

- Currently, bisphenol A epoxy resin is also produced by PCB manufacturers in China, with performance comparable to that of imported products.

- Although the gap between domestic copper clad laminate technology and foreign technologies has narrowed, European, American, and Japanese technologies still dominate in some high-end applications. Domestic resin manufacturers primarily produce bisphenol A epoxy resin, but there is still a gap in specialized resin technologies compared to Europe and the U.S.

- The primary resin used in copper clad laminates for general electronic products is bisphenol A epoxy resin. This type of resin contains halogens, which provide flame resistance. Most domestic manufacturers of such copper clad laminates currently use polytetrafluoroethylene resin.

Fillers and Hardener in Copper Clad Laminate Technology:

- The fillers used in the copper clad laminate formula are mainly silica (SiO2) and aluminum oxide (Al2O3). Currently, there is little difference between the fillers supplied by domestic and imported manufacturers.

- The curing agent for bisphenol A epoxy resin is produced domestically and is self-sufficient in China. For special resins, such as phenolic resins, the curing agents used are mainly sourced from Europe, the U.S., and Japan.

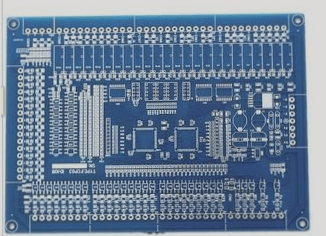

Laminated Combination Technology in PCB Manufacturing:

- A PCB rigid board cannot be bent, while a foldable circuit board is referred to as an FPC.

- In most cases, the PCB serves as the main board, with chips soldered onto it. FPC flexible boards are primarily used to connect components, such as flat cables, in electronic products. Compared to PCBs, they are lighter, more compact, and can be bent or folded.

- While certain special resins and curing agents still rely on imports, the copper clad laminate composite technology is domestically advanced.