2. The base film material of FPC ranges from the initial polyimide film to the heat-resistant film capable of withstanding soldering. The first-generation polyimide film suffers from issues such as high moisture absorption and a large thermal expansion coefficient. Therefore, the second-generation polyimide materials are preferred for high-density PCB circuits.

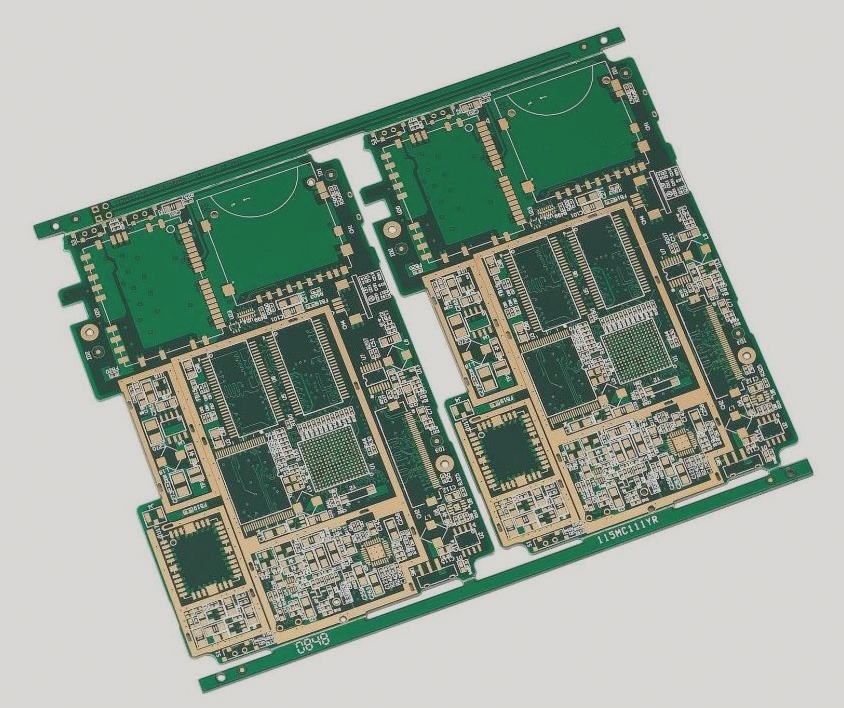

3. Copper clad laminate

4. Many FPC manufacturers often purchase copper clad laminates and subsequently process them into FPC products. The FPC copper-clad sheet or protective film (Cover Lay Film) using first-generation polyimide film employs adhesives such as epoxy resin or acrylic resin. However, the heat resistance of these adhesives is lower than that of polyimide, thereby limiting the overall heat resistance and other physical properties of FPC.

5. To overcome the limitations of traditional adhesive-based copper clad laminates, high-performance FPCs, including those for high-density circuits, employ adhesive-free copper clad laminates. Various manufacturing methods have been developed, with three practical methods currently available:

1) PCB Casting Process

The PCB casting process begins with copper foil as the starting material. A surface-activated copper foil is coated with liquid polyimide resin, which is then heat-treated to form a film. The polyimide resin must exhibit excellent adhesion to copper foil and superior dimensional stability. However, currently available polyimide resins do not fully meet both requirements simultaneously. Initially, a thin layer of polyimide resin (adhesive layer) with strong adhesion is applied to the activated copper foil surface. Subsequently, a thicker layer of polyimide resin with good dimensional stability (core layer) is coated over the adhesive layer. Due to differing thermal and physical properties of these polyimide resins, etching the copper foil may result in significant pits in the base film. To mitigate this issue, an adhesive layer is applied to the core layer to achieve symmetrical properties in the base layer.

For manufacturing double-sided copper-clad boards, a thermoplastic (Hot Melt) polyimide resin is used for the adhesive layer, followed by a hot pressing method to laminate the copper foil onto the adhesive layer.

2) Sputtering/Plating Process

The sputtering/plating process starts with a heat-resistant film known for its dimensional stability. Initially, a sputtering process is employed to create a seeding layer on the activated polyimide film surface. This seeding layer ensures strong bonding to the conductor base layer and serves as the conductor layer for subsequent electroplating. Typically, nickel or a nickel alloy is used. To ensure conductivity, a thin layer of copper is sputtered onto the nickel or nickel alloy layer, followed by electroplating copper to a specified thickness.

3) Hot Pressing Method

In the hot pressing method, a thermoplastic resin (thermoplastic adhesive resin) is coated onto a heat-resistant polyimide film with excellent dimensional stability. Subsequently, copper foil is laminated onto the hot-melt resin at high temperature. This method employs a composite polyimide film commercially available from specialized manufacturers. The manufacturing process is relatively straightforward. When producing copper-clad laminates, the composite film and copper foil are laminated together and subjected to high-temperature hot pressing. This method requires relatively modest equipment investment, making it suitable for small-scale production and diverse product types. It also simplifies the manufacture of double-sided copper-clad laminates.

An essential component of FPC is the protective layer (Cover Lay), with various materials proposed for this purpose. Initially, a practical protective layer involves coating the same heat-resistant film used as the substrate and employing the same adhesive as in copper-clad laminates. This structure offers good symmetry and remains predominant in the market, often referred to as “Film Cover Lay.” However, automating the processing of this film protection layer is challenging, increasing overall manufacturing costs. Moreover, fine window processing is difficult, limiting its suitability for high-density SMT applications that are increasingly prevalent.

To meet the demands of high-density mounting, photosensitive protective layers have gained traction in recent years. These involve applying photosensitive resin to the copper foil circuit and using PCB photolithography to create necessary openings. Photosensitive resin materials are available in liquid and dry film forms. Current protective layer materials based on epoxy resin or acrylic resin have been put into practical use, but their physical properties, particularly mechanical strength, are inferior to those of polyimide-based protective layers. Addressing this challenge requires either using polyimide resin or enhancing the physical properties of epoxy resin or acrylic resin materials used in PCB processes. The photosensitive polyimide resin holds promise for use as an interlayer insulating material in multilayer circuit formation processes.