Selective Soldering in PCB Manufacturing: A Comprehensive Guide

In the ever-evolving PCB board electronics industry, manufacturers are increasingly turning to selective soldering as a preferred method in the soldering process. This shift is driven by the numerous advantages it offers over traditional methods.

Advantages of Selective Soldering:

- Simultaneous soldering of all joints reduces production costs

- Minimizes temperature differentials encountered in reflow soldering

- Less impact on sensitive components

- Compatible with future lead-free soldering requirements

Process Characteristics:

Selective soldering differs from wave soldering in how the solder interacts with the PCB. While wave soldering submerges the entire lower section of the PCB in liquid solder, selective soldering targets specific areas. This precision minimizes heat exposure to adjacent components and areas, preserving their integrity during the soldering process.

Key Steps in Selective Soldering:

- Flux spraying

- PCB preheating

- Dip soldering

- Drag soldering

Flux Coating Process:

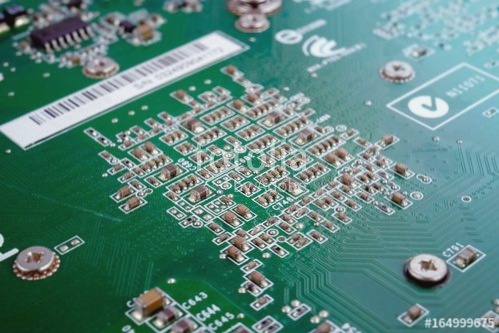

Flux spraying is a critical step in selective soldering to prevent bridging and oxidation of the PCB. The process involves precise application of flux to soldering positions using advanced techniques like micro-hole spray or synchronized multi-point spray methods.

Preheating Process:

Preheating optimizes flux viscosity before soldering, reducing thermal stress on the PCB. Temperature adjustments are made based on PCB thickness, device packaging, and flux type, with varying approaches to preheating based on specific requirements.

Soldering Techniques:

Selective soldering employs drag soldering and dip soldering techniques. Drag soldering is ideal for tight spaces and offers superior heat transfer efficiency compared to dip soldering. Parameters like solder temperature and drag speed play a crucial role in ensuring stable and reliable solder joints.

Machine Features:

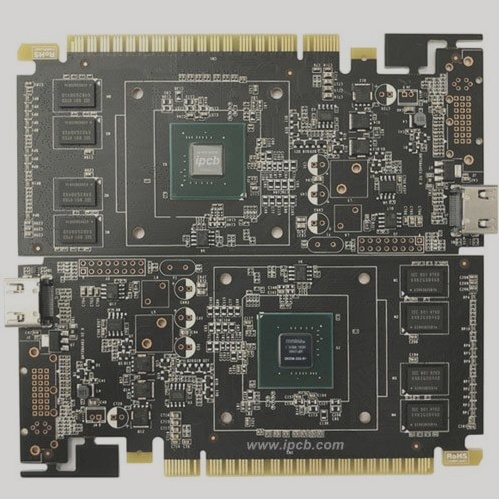

Selective soldering machines are known for their precision and flexibility. Modular designs allow customization for unique production needs, while manipulators offer precise positioning and movement for optimal PCB contact with the tin surface, resulting in high-quality welding outcomes.

Enhancing Throughput in Selective Soldering

Single-nozzle drag soldering processes, while advantageous, can experience longer cycle times due to sequential flux spraying, preheating, and soldering stages. This efficiency limitation becomes more apparent as the quantity of solder joints increases, especially when compared to the throughput of traditional wave soldering methods.

Fortunately, advancements in selective soldering technology have led to innovations such as dual-nozzle designs. These designs have the potential to significantly enhance throughput, addressing the challenges posed by single-nozzle processes and showcasing the continuous evolution of soldering techniques.