Understanding the Circuit Board Copper Sinking Process

Introduction

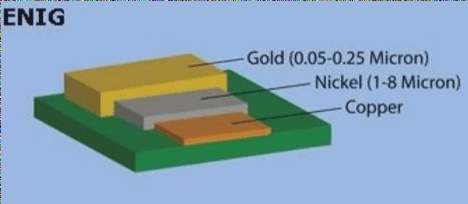

Electroless copper plays a crucial role in the production of printed circuit boards with through holes. It involves depositing a layer of copper on a non-conductive substrate through chemical treatments and then thickening it via electroplating methods. The thickness is typically designed to be 1mil (25.4um) or more.

Key Points

- Plated Through Holes: These holes are essential for forming conductor circuits or interlayer interconnection lines.

- Substrate Types:

- PI Polyimide Resin: Ideal for flexible board (FPC) production with high-temperature requirements.

- Phenolic Paper: Can be stamped and suitable for specific grades like FR-2 and XXX-PC.

- Epoxy Paper: Offers better mechanical properties than phenolic cardboard, with grades like CEM-1 and FR-3.

- Epoxy Glass Fiber: Utilizes glass fiber cloth for reinforcement, providing excellent mechanical properties with grades such as FR-4, FR-5, G-10, and G-11.

- Non-Woven Glass Fiber Polyester: Suited for special purposes with common grades like FR-6.

- Chemical Copper/Immersion Copper: Metallizing holes in non-conductive substrates enhances solderability and interlayer interconnects. This process is crucial for multi-layer boards.

Process Details

In the wet slurry process, holes are treated with spray nozzles using chemical materials to dissolve polymer resin. Post-treatment is vital to prevent issues like poor copper deposition. Processes like the Chromic Acid Method and Concentrated Sulfuric Acid Method are used, each requiring specific treatments for optimal results.

Chromic Acid Method

Hexavalent chromium in the hole can hinder chemical copper coverage, requiring secondary activation. However, the cost and maturity of this process can be challenging. Neutralization steps using sodium bisulfite are essential to reduce hexavalent chromium to trivalent chromium for effective activation.

Concentrated Sulfuric Acid Method

After treatment, thorough washing with hot water is crucial to avoid residue formation that may interfere with plating. Residues like sodium salt from epoxy resin sulfonate can lead to contamination and plating difficulties if not properly cleaned.

Alternative Methods for PCB Desmear/Drill and Etch Back Processes

Aside from the traditional methods, there are several other chemical approaches utilized in PCB desmear/drill and etch back processes. One notable technique involves the utilization of a blend of organic solvents (bulking/swelling resins) along with potassium permanganate treatment. This approach has been increasingly adopted as a post-treatment alternative to the conventional concentrated sulfuric acid treatment and chromic acid method.

Moreover, there is ongoing experimentation with the plasma method for these processes. Although still in the experimental phase, the plasma method poses challenges for large-scale production due to substantial equipment investment requirements.