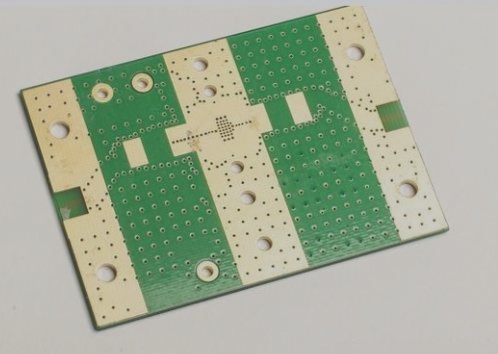

Low Volume PCB Assembly: The Ultimate Solution for Your PCB Needs

Have you ever needed a PCB (printed circuit board) for a project but not on a large scale? Low volume PCB assembly could be the answer to your problem. This method optimizes PCB integrity in a cost-effective way.

If you want to learn more about low volume PCB assembly, its advantages, service types, and prototyping options, check out the article here.

Advantages of Low Volume PCB Assembly

- Feasible layout modifications before full-scale production

- Rigorous testing to ensure compliance with client requirements

- Guaranteed quality standards by focusing on testing fewer boards initially

- Cost-effective production leading to minimized costs and enhanced reliability

Types of Assembly Services

DFM (Design for Manufacturing) involves integrity checks on engineering documents, while DFT (Design for Testing) includes test point placement in PCBs to aid in the manufacturing process.

Good PCB layout is crucial for successful PCB development. Understanding various possibilities enables skillful PCB design, influencing both assembly and wise particle application.

Prototyping Techniques

Prototyping techniques like Sequential and Parallel prototyping help in validating layouts and reducing manufacturing risks before full production.

PCB Assembly Configurations

- Do not place (DNP): Avoiding placement of specific components during testing or troubleshooting

- Use of multiple variants: Employing different components on PCBs for analysis

- Lead-free solder re-workability: Opting for leaded soldering for easier reworking

- Surface finish for re-workability: Choosing finishes that facilitate easy rework

By understanding low volume PCB assembly and utilizing DFT and DFM, you can effectively manage specific execution challenges. Make informed decisions for your PCB needs.

Enhance PCB Performance with Professional Assistance

Looking to boost your PCB performance without breaking the bank? It’s time to consider engaging professional assistance. With a wide range of services to choose from, finding the right provider is key to unlocking unparalleled support for your PCB needs.

Don’t settle for subpar performance – contact experienced professionals today to get the best assistance for your PCB projects.