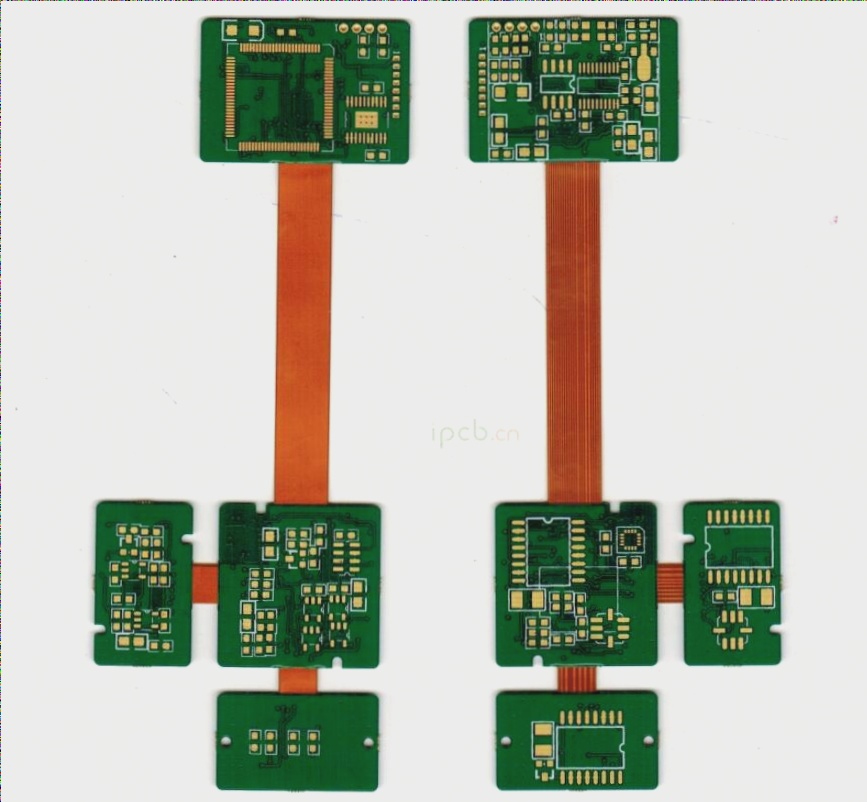

FPC Electroplating on Flexible Circuit Boards

Pre-treatment for FPC Electroplating

During the FPC coating process, it is crucial to remove contaminants and oxide layers from the copper conductor’s surface to achieve a dense coating with strong adhesion. Some contaminants may bond tightly and require alkaline abrasives for removal. The pre-treatment cleaning process significantly impacts the FPC’s fundamental characteristics.

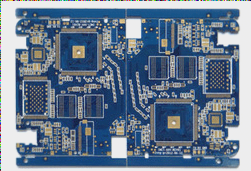

Thickness of FPC Electroplating

The deposition rate of electroplated metal is influenced by the electric field intensity, which varies based on the circuit pattern’s shape. To ensure uniform plating thickness, a shunt cathode pattern can be added around the circuit to absorb uneven current distribution. Careful attention to the electrode structure is essential for consistent coating thickness.

Stains and Contaminants in FPC Electroplating

Stains, dirt, and discoloration can appear on the electroplated layer due to insufficient rinsing, leading to slow chemical reactions over time. Thorough rinsing and drying, along with a high-temperature thermal aging test, can prevent these issues.

Electroless Plating on Flexible Circuit Boards

When line conductors cannot serve as electrodes for electroplating, electroless plating is used. The strong chemical activity of electroless plating solutions, such as electroless gold plating, can penetrate beneath the covering layer if bonding strength is insufficient.

Flexible Circuit Board FPC Hot Air Leveling

The Hot Air Leveling Process in PCB Fabrication

Hot air leveling, originally developed for rigid printed board PCB coating with lead and tin, has now been adapted for flexible printed boards (FPC). This process entails immersing the board into a molten lead-tin bath and using hot air to remove excess solder.

Challenges with Flexible Printed Boards

- Flexible printed boards require precautions before immersion in solder, often needing to be clamped between titanium steel screens.

- The board surface must be cleaned and coated with flux prior to the hot air leveling process.

Potential Issues

The harsh conditions of hot air leveling can lead to solder penetration from the cover layer edge into the underlying area, especially if the bonding strength is low. Moisture absorption by polyimide film can result in bubbling or peeling of the cover layer during the process due to rapid heat evaporation.

Precautions to Take

It is crucial to thoroughly dry and moisture-proof FPCs before subjecting them to hot air leveling to prevent issues caused by moisture absorption.

If you have any PCB manufacturing needs, feel free to contact us.

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย