1. The concept of PCB residual copper rate: The PCB manufacturing process begins with a PCB “substrate” composed of glass epoxy (Glass Epoxy) or similar materials.

2. The first step in production is to lightly sketch the PCB design wiring between the components. This is done by “printing” the negative of the designed PCB circuit board onto the metal conductor using a subtractive transfer method.

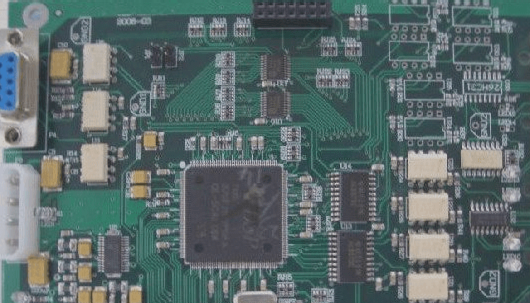

3. This technique involves spreading a thin layer of copper foil across the entire surface and then removing the excess. For double-sided boards, both sides of the PCB substrate are covered with copper foil.

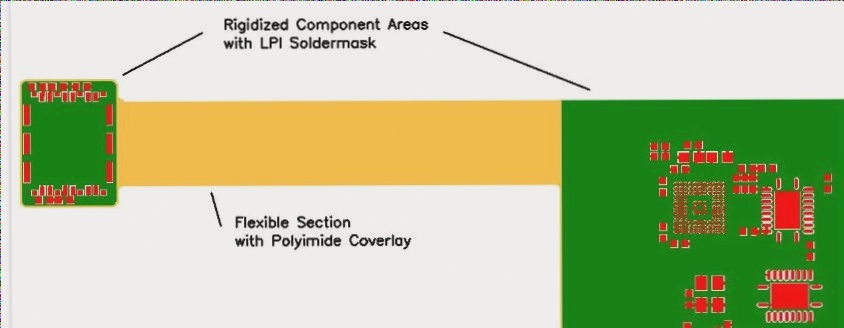

4. To create a multi-layer board, two double-sided boards can be “pressed” together using a special adhesive.

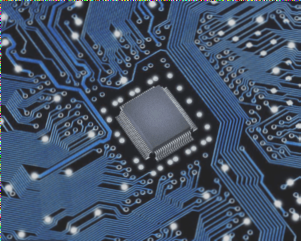

2. The first step in production is to lightly sketch the PCB design wiring between the components. This is done by “printing” the negative of the designed PCB circuit board onto the metal conductor using a subtractive transfer method.

3. This technique involves spreading a thin layer of copper foil across the entire surface and then removing the excess. For double-sided boards, both sides of the PCB substrate are covered with copper foil.

4. To create a multi-layer board, two double-sided boards can be “pressed” together using a special adhesive.