9. The after-sales maintenance of the product is assured.

10. If the number of components is small and hard to procure, the PCBA factory will handle the issue.

11. With access to excellent supplier channels and maintaining stable, long-term cooperative relationships, component procurement quality is guaranteed, and cost control is facilitated.

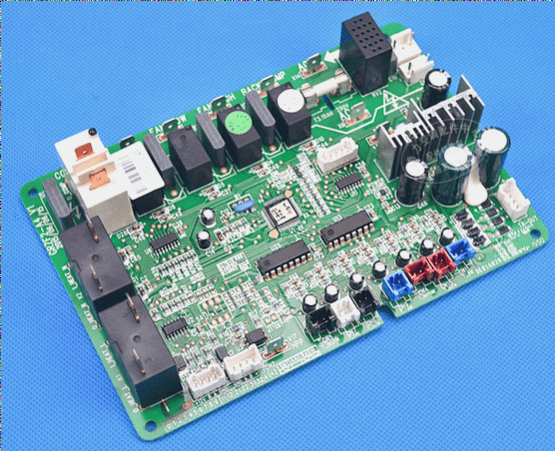

12. Reducing production linkages enhances quality traceability and consistency. PCB manufacturing, component procurement, PCB processing, and test assembly are all completed within a single factory.

13. Efficiently utilizing resources and reducing unnecessary expenses are key. Design, R&D, and production are distinct stages where specialists handle specific tasks, leading to higher efficiency, better quality assurance, and easier cost management.

14. Integrating components and materials reduces redundant purchases, minimizes losses, and lowers company costs.

15. Cutting down on communication costs and speeding up time-to-market is crucial. Avoid the need for separate coordination of components, PCBs, and test assemblies. In today’s fast-evolving technology landscape, time is critical.

16. Offering professional one-stop PCBA custom processing, handling various cases and industry-specific situations, and possessing extensive experience in managing unexpected challenges during new product production.

The advantages of PCBA processing are numerous and its popularity is on the rise. Given the frequent involvement of electrostatic-sensitive components, anti-static measures are essential, alongside other precautions. This process demands high technical expertise, with equipment such as printers, dispensers, and placement machines operated by skilled professionals.