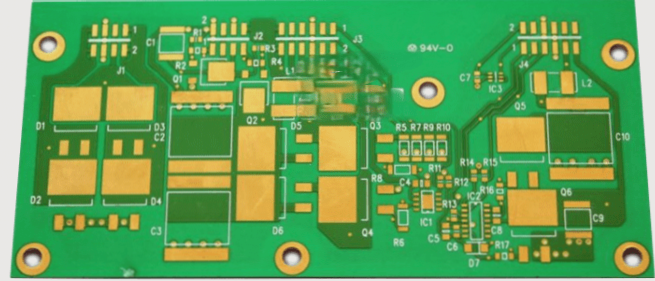

The Importance of Precautions and Design Specifications in PCB Design

- When using PADS’s PowerPCB software for printed circuit board design, it is essential to follow specific precautions to ensure optimal performance.

- Design specifications play a crucial role in enhancing communication and facilitating mutual inspection among designers within a working group.

- Errors, such as spacing issues due to connectors extending beyond the board frame, should not be overlooked during checks.

- Regular re-plating of copper is necessary after modifying traces and vias to maintain the board’s performance.

Review Process

The review process, based on the “PCB checklist,” evaluates design rules, layer definitions, line widths, spacing, pad configurations, and via settings. It focuses on aspects like device layout rationality, power and ground network routing, and high-speed clock networks. Designers must make modifications if the recheck results are unsatisfactory, with final approval requiring signatures from both the rechecker and the designer.

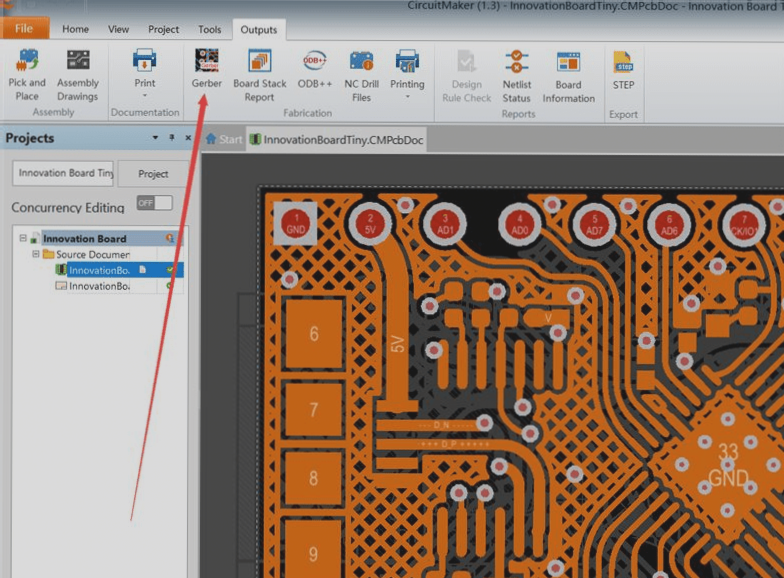

Design Output and Gerber Files

The PCB design can be exported to a printer or a Gerber file for production. Considerations for generating the Gerber file include outputting wiring layers, power layers, silk screen layers, solder mask layers, and drilling files. Specific settings, such as Aperture values and layer configurations, are crucial for accurate output. Reviewing the Gerber files using CAM350 is essential before finalizing the design.