he customer’s test requirements and standards. The test equipment and fixtures should be regularly maintained and calibrated to ensure the accuracy and reliability of the test results.

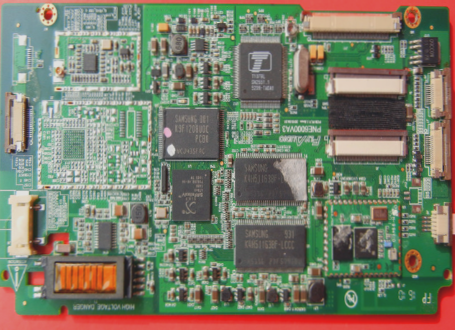

7. Aging Test

After the PCBA board is assembled, it needs to go through an aging test to simulate the working environment of the final product, and to detect potential defects caused by factors such as temperature, humidity, and vibration. This process can effectively improve the reliability and stability of the PCBA board.

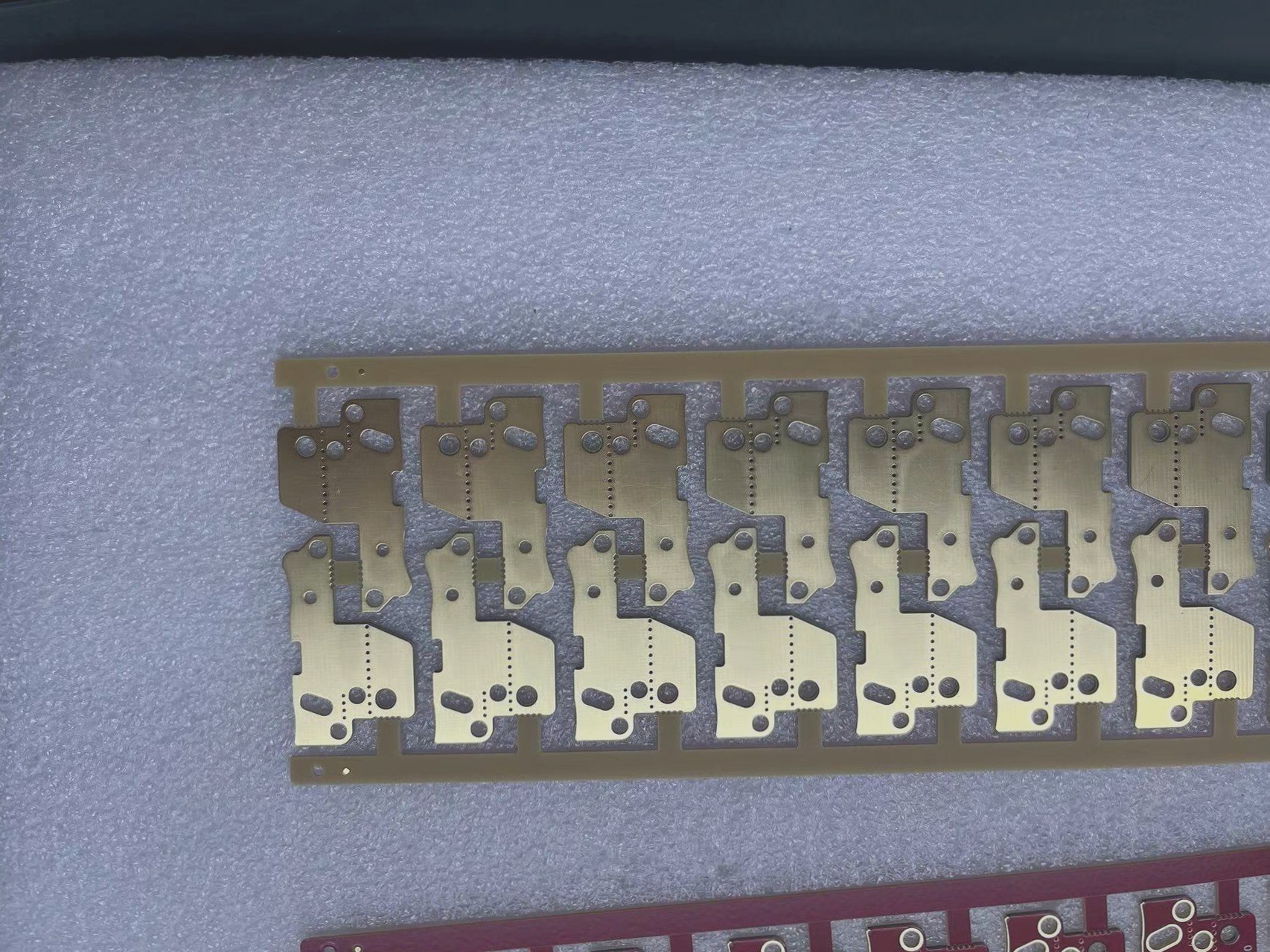

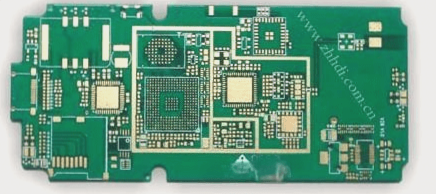

In summary, the PCBA manufacturing process involves multiple complex processes, and each process requires strict control and attention to detail. By focusing on PCB circuit board manufacturing, component procurement and inspection, SMT processing, plug-in processing, program firing, testing, and aging, we can ensure the quality and reliability of the final PCBA boards. It is important for PCB experts to continuously improve their knowledge and skills in each aspect, in order to meet the high standards of PCBA manufacturing.

7. Aging Test

After the PCBA board is assembled, it needs to go through an aging test to simulate the working environment of the final product, and to detect potential defects caused by factors such as temperature, humidity, and vibration. This process can effectively improve the reliability and stability of the PCBA board.

In summary, the PCBA manufacturing process involves multiple complex processes, and each process requires strict control and attention to detail. By focusing on PCB circuit board manufacturing, component procurement and inspection, SMT processing, plug-in processing, program firing, testing, and aging, we can ensure the quality and reliability of the final PCBA boards. It is important for PCB experts to continuously improve their knowledge and skills in each aspect, in order to meet the high standards of PCBA manufacturing.