PCB Drilling Methods and Tips for High-Density Circuits

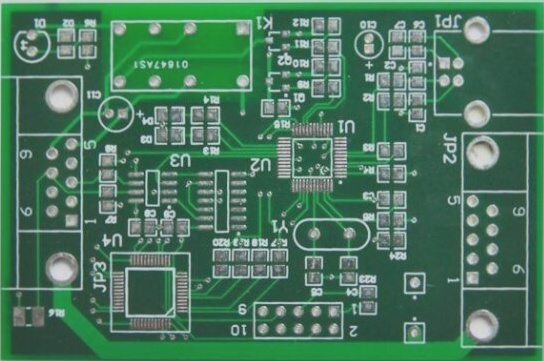

In the fast-evolving electronic industry, new products are constantly emerging with a focus on being “light, thin, short, and small.” As a result, PCBs are advancing towards higher density, complexity, and precision. The drilling process in PCB production plays a crucial role, especially with the introduction of various types of holes to meet manufacturing demands.

Types of PCB Drilling Methods:

- Through Hole (VIA): Conductive holes passing through the circuit board for interlayer connections.

- Buried Hole: Connections within PCB layers without extending to the outer layer.

- Blind Hole: Connects outer and inner layers without being visible on the opposite side.

Tips for Effective PCB Drilling:

- Through Hole: Utilize plug holes for stable production and reliable quality.

- Buried Hole: Drill holes at individual layers for high-density boards.

- Blind Hole: Pay attention to drilling depth for successful electroplating.

High-Speed PCB Design Considerations:

- Choose optimal via hole sizes for cost-effective and high-quality signal transmission.

- Utilize thinner PCB boards to reduce parasitic effects of vias.

- Minimize unnecessary vias to maintain signal integrity.

- Keep power and ground pins close with short leads to reduce impedance.

- Place grounded vias near signal switching layers for improved circuit stability.

By following these tips and understanding the different drilling methods, manufacturers can enhance the efficiency and reliability of their PCB production processes, meeting the demands of the ever-changing electronic market.

The Importance of Flexibility in PCB Design

Flexibility is a crucial aspect of PCB design, allowing for adaptability and customization based on specific requirements. When dealing with through hole models, where each layer features solder pads, it may be necessary to adjust the design to optimize performance.

- In high-density via scenarios, excessive solder pad sizes can create grooves in the copper layer, potentially affecting circuit separation.

- One solution is to strategically reposition vias to alleviate this issue.

- Additionally, reducing the size of the solder pads in the PCB drilling process can help maintain the integrity of the copper layer.