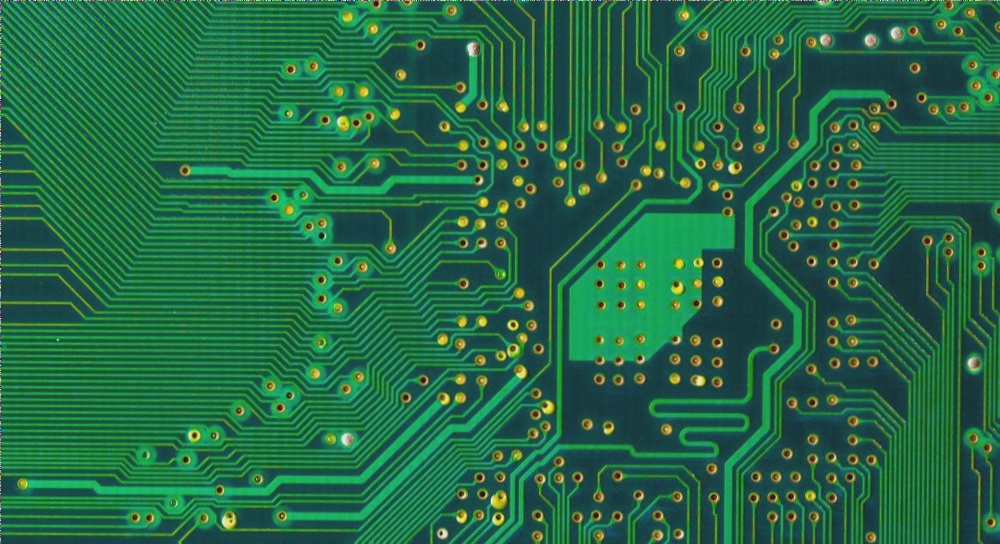

1. Copper-plated PCB board refers to a thin layer of copper formed on the copper electrode plate of a glass fiber chip. This layer is utilized to protect circuits, enhance conductivity, resist oxidation, and improve the appearance of the board.

The Function and Process of PCB Copper Plating

The function of PCB Copper Plated board is to protect the newly deposited thin layer of chemical copper. Full board plated refers to the process of using the entire printed board as the cathode after hole metallization. The copper layer is thickened to a certain extent through plating, and then the circuit pattern is formed through etching to prevent the product from being scrapped due to the thin chemical copper layer being etched off by subsequent processes.

1) Firstly, copper electrodeposition can improve the mechanical strength of PCB boards. Copper is a metal with high elasticity and toughness, which can strengthen PCB boards.

2) Secondly, copper plating can improve the conductivity of PCB boards. Copper is an excellent conductive material that can improve the conductivity of PCB circuit circuits.

3) Copper plating can improve the corrosion resistance of PCB boards. The copper electrodeposition layer can effectively protect PCB boards from oxidation, corrosion, and other chemical reactions.

The Process of Copper Plated PCB Board

1. Firstly, we need to prepare the copper plating solution. The main components of the copper solution are copper sulfate and tartaric acid. This process requires strict reaction time and temperature, otherwise, it will result in an unusable copper solution.

2. We need to preprocess the PCB board. The purpose of pre-treatment is to clean and activate the copper layer on the surface of the PCB board, which is the key to ensuring uniform copper plating on the PCB board surface.

3. Then, we need to immerse the PCB board in a copper plating solution. During this process, copper ions will gradually deposit on the surface of the PCB board, forming a uniform copper electrodeposition layer. This process requires controlling the deposition time and temperature to ensure the thickness and uniformity of the copper layer on the surface of the PCB board.

4. Finally, we need to perform cleaning and post-treatment. This process includes cleaning the PCB board, removing areas that have not been coated with copper, and post-processing operations such as protecting the PCB board from corrosion.

The Difference Between Copper Sinking and Copper Plating

Copper precipitation is the process of placing copper products in a copper saltwater solution containing copper ions, and using electrochemical principles to reduce copper ions on the surface of copper products to achieve the purpose of protection or decoration. The process flow is simple, but it is necessary to consider factors such as the concentration and temperature of copper ions, as well as the control of treatment time, to achieve the desired effect.

Sinking copper is suitable for products with low requirements for protection and appearance, such as cultural artworks and practical daily necessities such as incense burners, Buddha statues, lamps, and tableware. Its advantage is low cost and does not cause the product to lose its original texture and color.

The process of copper plating requires the copper product to be decontaminated, pickled, and washed before being immersed in a solution containing copper salt and citrate. The current from an external power source is used to reduce copper ions on the surface of the copper product, forming a uniform and strong adhesion copper coating. Due to its relatively complex process, it requires professional technical personnel to control it.

Copper plating is suitable for fields that require high corrosion resistance, conductivity, and aesthetics of products, such as mechanical equipment, automobiles, electronic components, and high-end tableware. Its advantages are uniform copper coating, high glossiness, strong adhesion, good corrosion resistance, and a certain degree of conductivity and thermal conductivity.

Copper-plated PCB board is a crucial step in PCB manufacturing. By plating copper, the mechanical strength, conductivity, and corrosion resistance of the PCB board can be ensured, thereby ensuring the quality and performance of the PCB board.

The Function and Process of PCB Copper Plating

The function of PCB Copper Plated board is to protect the newly deposited thin layer of chemical copper. Full board plated refers to the process of using the entire printed board as the cathode after hole metallization. The copper layer is thickened to a certain extent through plating, and then the circuit pattern is formed through etching to prevent the product from being scrapped due to the thin chemical copper layer being etched off by subsequent processes.

1) Firstly, copper electrodeposition can improve the mechanical strength of PCB boards. Copper is a metal with high elasticity and toughness, which can strengthen PCB boards.

2) Secondly, copper plating can improve the conductivity of PCB boards. Copper is an excellent conductive material that can improve the conductivity of PCB circuit circuits.

3) Copper plating can improve the corrosion resistance of PCB boards. The copper electrodeposition layer can effectively protect PCB boards from oxidation, corrosion, and other chemical reactions.

The Process of Copper Plated PCB Board

1. Firstly, we need to prepare the copper plating solution. The main components of the copper solution are copper sulfate and tartaric acid. This process requires strict reaction time and temperature, otherwise, it will result in an unusable copper solution.

2. We need to preprocess the PCB board. The purpose of pre-treatment is to clean and activate the copper layer on the surface of the PCB board, which is the key to ensuring uniform copper plating on the PCB board surface.

3. Then, we need to immerse the PCB board in a copper plating solution. During this process, copper ions will gradually deposit on the surface of the PCB board, forming a uniform copper electrodeposition layer. This process requires controlling the deposition time and temperature to ensure the thickness and uniformity of the copper layer on the surface of the PCB board.

4. Finally, we need to perform cleaning and post-treatment. This process includes cleaning the PCB board, removing areas that have not been coated with copper, and post-processing operations such as protecting the PCB board from corrosion.

The Difference Between Copper Sinking and Copper Plating

Copper precipitation is the process of placing copper products in a copper saltwater solution containing copper ions, and using electrochemical principles to reduce copper ions on the surface of copper products to achieve the purpose of protection or decoration. The process flow is simple, but it is necessary to consider factors such as the concentration and temperature of copper ions, as well as the control of treatment time, to achieve the desired effect.

Sinking copper is suitable for products with low requirements for protection and appearance, such as cultural artworks and practical daily necessities such as incense burners, Buddha statues, lamps, and tableware. Its advantage is low cost and does not cause the product to lose its original texture and color.

The process of copper plating requires the copper product to be decontaminated, pickled, and washed before being immersed in a solution containing copper salt and citrate. The current from an external power source is used to reduce copper ions on the surface of the copper product, forming a uniform and strong adhesion copper coating. Due to its relatively complex process, it requires professional technical personnel to control it.

Copper plating is suitable for fields that require high corrosion resistance, conductivity, and aesthetics of products, such as mechanical equipment, automobiles, electronic components, and high-end tableware. Its advantages are uniform copper coating, high glossiness, strong adhesion, good corrosion resistance, and a certain degree of conductivity and thermal conductivity.

Copper-plated PCB board is a crucial step in PCB manufacturing. By plating copper, the mechanical strength, conductivity, and corrosion resistance of the PCB board can be ensured, thereby ensuring the quality and performance of the PCB board.