Technologies Related to Multi-Chip Modules

This article delves into the advancements in multi-chip module (MCM) technologies. The increasing demand for cost-effective solutions in consumer electronics has led to the widespread adoption of PCBA MCM technology. For products requiring high-density integration to achieve superior performance, miniaturization, and cost-effectiveness, PCBA MCM offers a variety of packaging technologies.

1. MGM Overview

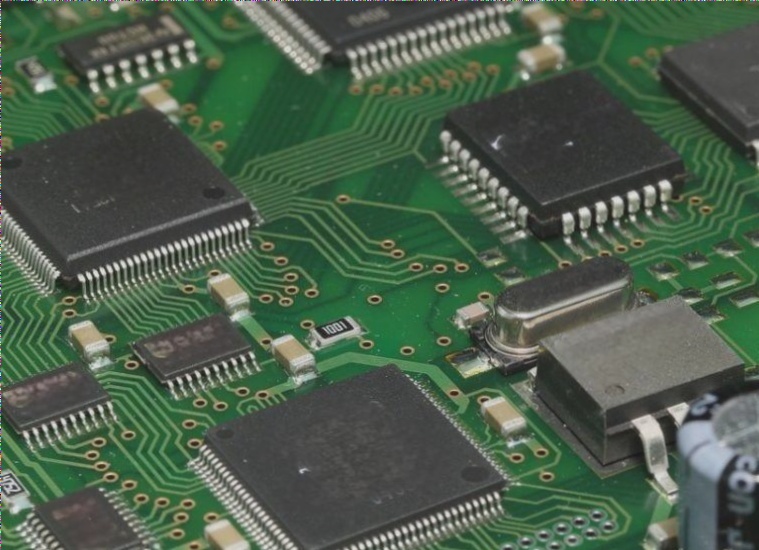

PCBA MCM refers to a module that comprises two or more bare chips or chip-scale package (CSP) ICs assembled onto a substrate. These modules form an electronic system or subsystem. The substrate can be a printed circuit board (PCB), thick/thin film ceramic, or a silicon wafer with interconnection patterns. The entire PCBA MCM can be packaged on the substrate and encapsulated within the package body. This package may be a standardized component designed for easy installation on a circuit board or a module with embedded electronic functions, all of which can be directly integrated into various electronic systems like PCs, instruments, and mechanical equipment.

2. MGM Technology

The PCBA MCM technology can be categorized into three main types: PCBA MCM-L, PCBA MCM-C, and PCBA MCM-D. PCBA MCM-L utilizes a sheet-like multilayer substrate and is suitable for bonding and PC processes but may lack reliability in high-temperature environments. PCBA MCM-C employs multilayer ceramic substrates and is versatile across various applications. PCBA MCM-D, based on thin film technology, features a substrate with deposited multilayer dielectric, metal layers, and base materials like silicon, aluminum, alumina ceramic, or aluminum nitride, offering precise interconnection impedances and integration possibilities for resistors, capacitors, and protection circuits.

3. Market Driving Forces of PCBA MCM

- Size Reduction: PCBA MCM allows for a higher chip area percentage on PCBs, leading to significant size reduction.

- Technology Integration: Integration of digital and analog functions without limitations, combining application-specific integrated circuits with standard processors/memories, and incorporating passive components for enhanced flexibility.

- Data Speed and Signal Quality: Enhanced signal transmission characteristics with lower total capacitance and inductive load, providing better electromagnetic interference resistance.

- Reliability and Use Environment: Smaller systems offer improved protection against electromagnetic, water, gas, and other hazards compared to larger electronic systems.