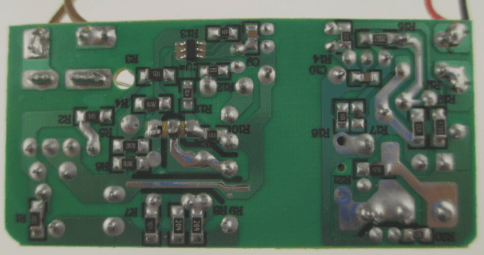

The Role of Capacitors in PCB Design

Capacitors in a PCB design play a crucial role in storing electric charge and serving as energy storage components. Understanding the structure and characteristics of capacitors is essential for efficient PCB design.

Capacitance and Charge in Conductors

Capacitance is the ability of a conductor to hold charge, where the charge (Q) is proportional to the potential (V) across the conductor, represented by the formula Q = CV. The unit of capacitance in PCB design is the Farad (F).

Insulating Medium in PCB Capacitors

In PCB design, an insulating medium separates two metal plates to form a capacitor. The capacitance of the PCB capacitor is crucial for energy storage. It is important to balance voltage and resistance to prevent breakdown and short circuits.

RC Charging and Discharging Model

The RC charging and discharging circuit model is used in PCB design. A larger series resistance (R) results in a slower charging current and longer charging time, while a larger capacitance (C) requires more energy storage and extends charging time.

Optimizing PCB Design

Optimizing the layout of internal components, metal connections, through holes, electromagnetic protection, and heat dissipation can enhance circuit performance and reduce production costs in PCB design.