Chip Testing: Enhancing Quality and Reliability

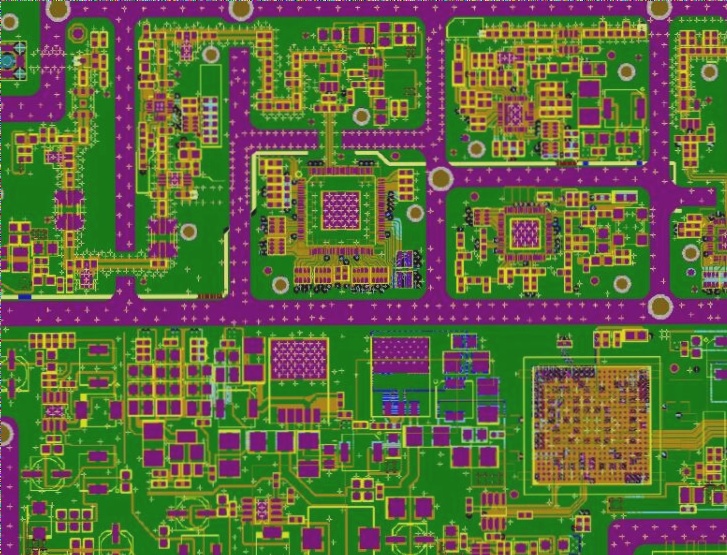

Chip testing plays a crucial role in ensuring the functionality and performance of semiconductor chips. There are two main categories of chip testing: wafer testing (CP testing) and finished product testing (FT testing).

Wafer Testing (CP Testing)

Wafer testing involves testing the electrical capacity and circuit functions of each chip on the wafer before packaging. This step ensures that the chips meet the required standards and can function properly in the final product.

Finished Product Testing (FT Testing)

Finished product testing is conducted after chip packaging to further verify the quality and functionality of the chips. Customized testing services are often provided to meet specific customer requirements and improve the overall product quality.

The Evolving Chip Testing Industry

With the rapid growth of the chip design industry, the demand for test chip services is increasing. Companies without testing capabilities face challenges in moving from design to production. This gap underscores the importance of reliable test chip services.

Market Trends and Opportunities

The test chip market is witnessing significant growth, especially in regions like China. Companies like Jinyu Semiconductor are investing in advanced testing equipment and skilled teams to meet the industry’s evolving needs.

Chip Aging Testing

Chip aging testing is a critical method to detect electrical faults in semiconductor components. By simulating the chip’s lifespan under stress conditions, this testing method helps assess reliability and detect early failures in devices.

As the semiconductor industry continues to evolve, the demand for high-end test chip services is on the rise. Companies that invest in advanced testing capabilities and adapt to industry changes are poised to succeed in this dynamic market.

Aging Testing in Semiconductor Devices

Aging testing is a crucial technology in the semiconductor industry, ensuring the reliability of components before integration into systems. This testing involves subjecting semiconductor components to specific conditions to analyze their performance and load capacity.

Benefits of Aging Testing

- Accelerates verification of equipment’s actual service life

- Highlights weaknesses in equipment packaging and chips

- Detects potential defects early on

Types of Failures

There are three main types of failures observed during aging testing:

- Early Failures: Occur in the initial stages of operation and decrease over time.

- Random Faults: Have a constant occurrence rate over a long period.

- Wear Failures: Happen towards the end of the component’s shelf life.

If semiconductor devices experience early failures, the risk of random or wear failures diminishes as their lifespan is cut short. Detecting and addressing potential defects through aging testing is crucial to ensuring product reliability and longevity.