FR4 is the code for the fire-resistant material grade, indicating that the resin material must be able to self-extinguish during the burning process. It does not refer to a specific material, but rather to a material grade. As a result, there are various types of FR4 grade materials used in circuit boards, with the majority being composite materials made from a four-function epoxy resin, filler, and glass fiber.

FR4 is a glass fiber epoxy resin copper clad plate. The glass fiber is manufactured through high-temperature melting, drawing, winding, weaving, and other processes using pyrophyllite, quartz sand, limestone, dolomite, boracite, and brucite. The monofilament diameter ranges from several microns to more than 20 microns, equivalent to 1/20-1/5 of a hair filament. Each bundle of fiber precursor is composed of hundreds or even thousands of monofilaments.

FR4 is a grade for fire-resistant material, indicating that the resin material must be able to self-extinguish after burning. It is not a specific material name, but rather a material grade. As a result, there are currently various types of FR4 grade materials used in general circuit boards, with the majority being composite materials made from a four-function epoxy resin, filler, and glass fiber.

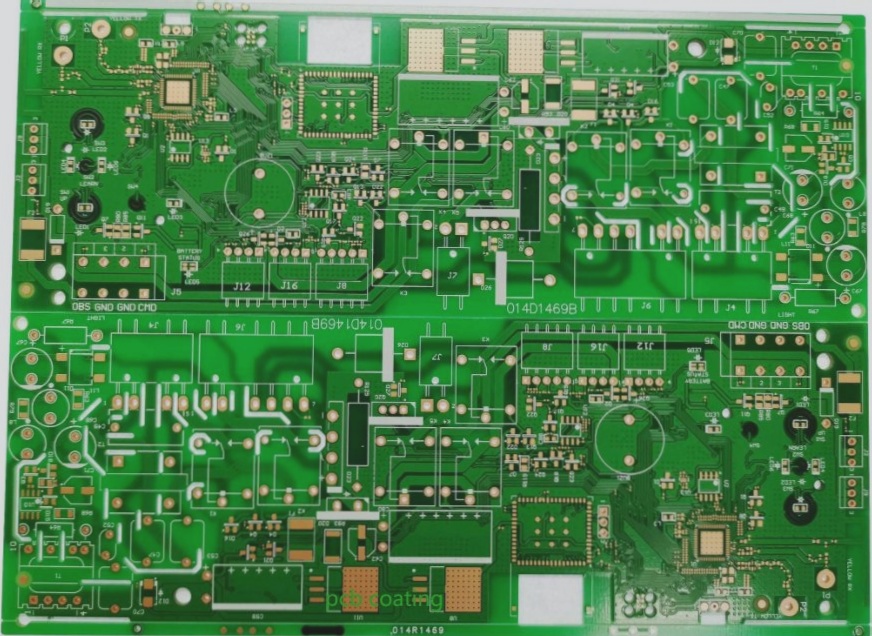

fr4 plate

Conventional thickness of fr4 material

The commonly used thicknesses are 0.3 mm, 0.4 mm, 0.5 mm, 0.6 mm, 0.8 mm, 1.0 mm, 1.2 mm, 1.5 mm, 1.6 mm, 1.8 mm and 2.0 mm. The plate thickness error is determined according to the manufacturing capacity of the plate factory. The common copper thickness of fr4 copper clad plate is 0.5 oz, 1 oz and 2 oz, and other copper thicknesses are also available.

Features of fr 4 material

FR4 epoxy glass fiber cloth substrate is a kind of substrate with epoxy resin as adhesive and electronic glass fiber cloth as reinforcing material. Its adhesive sheet and inner core thin copper clad plate are the primary substrate for the production of multilayer printed circuit boards. CCL is widely used, and all performance indicators can meet the needs of general industrial electronic products. Glass fiber has very good ultimate tensile strength, higher than most metals. It is an excellent insulator with very low coefficient of thermal expansion and corrosion resistance and weather resistance. Low water absorption, good durability, good bending strength.

Fr4 sheet properties

FR4 has higher mechanical strength, dimensional stability, impact resistance and moisture resistance than paper substrate. Its electrical performance is good, its working temperature is high, and its performance is less affected by the environment. In terms of processing technology, it has greater advantages than the glass fiber cloth base plate of other resins. This kind of product is mainly used in double-sided PCB, and the consumption is large.

Fr4 sheet application

FR4 is the most widely used product model. Due to the development of electronic product installation technology and PCB technology, fr 4 products with high Tg are produced. FR4 is mainly used for ordinary computers, instruments and meters, advanced household appliances and general electronic products. For general electronic goods, FR4 material is generally selected. It is not a material name, but a material grade. It represents a material specification that the resin material must be able to extinguish itself after burning.

FR4 is a glass fiber epoxy resin copper clad plate. The glass fiber is manufactured through high-temperature melting, drawing, winding, weaving, and other processes using pyrophyllite, quartz sand, limestone, dolomite, boracite, and brucite. The monofilament diameter ranges from several microns to more than 20 microns, equivalent to 1/20-1/5 of a hair filament. Each bundle of fiber precursor is composed of hundreds or even thousands of monofilaments.

FR4 is a grade for fire-resistant material, indicating that the resin material must be able to self-extinguish after burning. It is not a specific material name, but rather a material grade. As a result, there are currently various types of FR4 grade materials used in general circuit boards, with the majority being composite materials made from a four-function epoxy resin, filler, and glass fiber.

fr4 plate

Conventional thickness of fr4 material

The commonly used thicknesses are 0.3 mm, 0.4 mm, 0.5 mm, 0.6 mm, 0.8 mm, 1.0 mm, 1.2 mm, 1.5 mm, 1.6 mm, 1.8 mm and 2.0 mm. The plate thickness error is determined according to the manufacturing capacity of the plate factory. The common copper thickness of fr4 copper clad plate is 0.5 oz, 1 oz and 2 oz, and other copper thicknesses are also available.

Features of fr 4 material

FR4 epoxy glass fiber cloth substrate is a kind of substrate with epoxy resin as adhesive and electronic glass fiber cloth as reinforcing material. Its adhesive sheet and inner core thin copper clad plate are the primary substrate for the production of multilayer printed circuit boards. CCL is widely used, and all performance indicators can meet the needs of general industrial electronic products. Glass fiber has very good ultimate tensile strength, higher than most metals. It is an excellent insulator with very low coefficient of thermal expansion and corrosion resistance and weather resistance. Low water absorption, good durability, good bending strength.

Fr4 sheet properties

FR4 has higher mechanical strength, dimensional stability, impact resistance and moisture resistance than paper substrate. Its electrical performance is good, its working temperature is high, and its performance is less affected by the environment. In terms of processing technology, it has greater advantages than the glass fiber cloth base plate of other resins. This kind of product is mainly used in double-sided PCB, and the consumption is large.

Fr4 sheet application

FR4 is the most widely used product model. Due to the development of electronic product installation technology and PCB technology, fr 4 products with high Tg are produced. FR4 is mainly used for ordinary computers, instruments and meters, advanced household appliances and general electronic products. For general electronic goods, FR4 material is generally selected. It is not a material name, but a material grade. It represents a material specification that the resin material must be able to extinguish itself after burning.