1. Do you know about the SMT surface mount assembly inspection process? SMT is a complex integrated system engineering technology characterized by high speed and precision. To achieve high throughput and reliable quality, we must manage various aspects including PCB design, components, materials, processes, equipment, and regulations.

2. Among these aspects, prevention-based process control is especially suited for SMT. In each “step of the manufacturing process” in SMT, it is crucial to prevent defects and potential issues from advancing to the next stage by employing effective detection methods. Therefore, “detection” is an indispensable and crucial part of process control.

3. SMT testing includes incoming inspection, process inspection, and surface mount board inspection, as well as the use of anti-static gloves and PU-coated gloves. PCBA is currently the most popular technology and process in the electronics assembly industry. It involves surface-mount components arranged in a matrix with either no leads, short leads, or balls, which are mounted on the surface of a printed circuit board or other substrates using reflow soldering or dip soldering techniques.

1. The quality issues identified during process inspection can be addressed through rework. During electronic printing production, PCBA proofing involves creating and precisely trimming negatives using photographic or electronic color separation methods, and printing them to produce proofs before electronic printing or employing other methods to demonstrate the plate-making effect.

2. Currently, one of the most widely used technologies in the electronics assembly industry involves mounting surface-mount components, which may have no leads or short leads, in a matrix arrangement on the surface of a printed circuit board or other substrates. This circuit assembly technology employs reflow soldering or dip soldering for assembly.

3. The rework cost for unqualified products identified during incoming inspection, solder paste printing, and pre-welding inspection is relatively low, with minimal impact on the reliability of electronic products.

4. However, reworking unqualified products after soldering poses significant challenges. This process requires PCB re-soldering following desoldering and involves additional working time, material costs, and potential damage to components and printed boards. Certain components, such as Flip chips needing underfill, are particularly difficult to repair. For instance, after repairing CSP, it is necessary to re-solder the ball.

5. Repairing embedded technology and multi-chip stacking is more complex. Therefore, when significant rework is needed after soldering, it is crucial to wear anti-static gloves and PU-coated gloves to prevent damage. Effective process inspections, especially the initial ones, can reduce defect and scrap rates, minimize rework and repair costs, and help prevent quality issues from the source through detailed defect analysis.

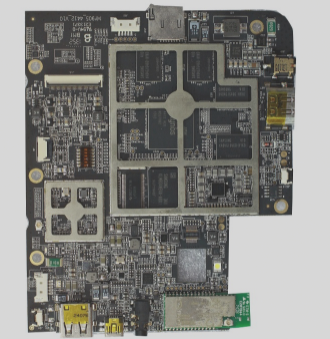

6. The final inspection of surface-mount boards is equally critical. Ensuring the delivery of qualified and reliable products to users is essential for market competitiveness. Testing includes visual inspection, component placement, model and polarity checks, solder joint inspection, and electrical performance and reliability testing.

2. Among these aspects, prevention-based process control is especially suited for SMT. In each “step of the manufacturing process” in SMT, it is crucial to prevent defects and potential issues from advancing to the next stage by employing effective detection methods. Therefore, “detection” is an indispensable and crucial part of process control.

3. SMT testing includes incoming inspection, process inspection, and surface mount board inspection, as well as the use of anti-static gloves and PU-coated gloves. PCBA is currently the most popular technology and process in the electronics assembly industry. It involves surface-mount components arranged in a matrix with either no leads, short leads, or balls, which are mounted on the surface of a printed circuit board or other substrates using reflow soldering or dip soldering techniques.

1. The quality issues identified during process inspection can be addressed through rework. During electronic printing production, PCBA proofing involves creating and precisely trimming negatives using photographic or electronic color separation methods, and printing them to produce proofs before electronic printing or employing other methods to demonstrate the plate-making effect.

2. Currently, one of the most widely used technologies in the electronics assembly industry involves mounting surface-mount components, which may have no leads or short leads, in a matrix arrangement on the surface of a printed circuit board or other substrates. This circuit assembly technology employs reflow soldering or dip soldering for assembly.

3. The rework cost for unqualified products identified during incoming inspection, solder paste printing, and pre-welding inspection is relatively low, with minimal impact on the reliability of electronic products.

4. However, reworking unqualified products after soldering poses significant challenges. This process requires PCB re-soldering following desoldering and involves additional working time, material costs, and potential damage to components and printed boards. Certain components, such as Flip chips needing underfill, are particularly difficult to repair. For instance, after repairing CSP, it is necessary to re-solder the ball.

5. Repairing embedded technology and multi-chip stacking is more complex. Therefore, when significant rework is needed after soldering, it is crucial to wear anti-static gloves and PU-coated gloves to prevent damage. Effective process inspections, especially the initial ones, can reduce defect and scrap rates, minimize rework and repair costs, and help prevent quality issues from the source through detailed defect analysis.

6. The final inspection of surface-mount boards is equally critical. Ensuring the delivery of qualified and reliable products to users is essential for market competitiveness. Testing includes visual inspection, component placement, model and polarity checks, solder joint inspection, and electrical performance and reliability testing.