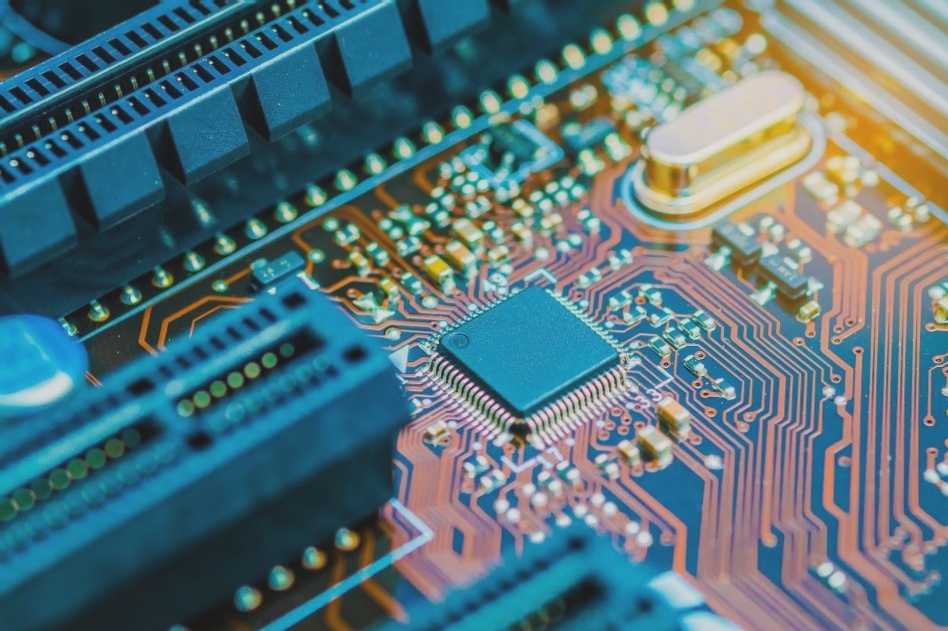

1. FCT testing is a type of testing performed on a PCB during the manufacturing process.

2. This test identifies short and open circuits in the PCB and ensures that the board functions correctly.

3. Additionally, FCT is a crucial step in PCB quality control, typically conducted after the soldering process.

**Advantages of Using FCT Testing on Circuit Boards**

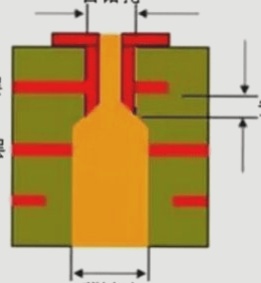

1. Switching testing fixtures enable testing of various FCT function testers. It is a tool used to verify whether a PCBA is qualified. It consists of two parts: the main part and the testing fixture part. The main part includes a computer system and a signal sampling system, which are universal. The testing fixture part has fixed dimensions and is designed with positioning holes for different target test boards. They are connected via flat cables. To test different boards, simply replace the testing fixture and load the corresponding testing program on the computer.

2. Test parameters can be configured: you can adjust, cancel, save new parameters for different frequency conversion boards, and retrieve them as needed.

3. The advantage of functional testing fixtures is that, even with less skilled operators, the same product can be produced efficiently with minimal defects and low variability.

The FCT test, or Functional Circuit Test, includes functions such as voltage and current measurement and control, power factor, frequency and duty cycle, position determination, LED lighting and color, sound recognition, and temperature and pressure measurement.

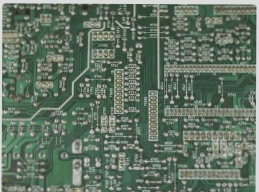

FCT targets the functionality of each circuit on the board, verifying whether it meets specifications and identifying open or short circuits. It precisely indicates defective parts and their causes. Thus, FCT inspection should be performed after the circuit board plug-in is welded to address issues like input/output testing, power supply voltage and power verification, open and short circuit testing, simulation of signal control boards, and ensuring normal circuit board functionality, dynamic function testing, automatic testing, and overall product quality improvement.

FCT is crucial as it ensures PCB functionality and identifies manufacturing defects before shipping, saving both time and cost.

FCT testing benefits PCB components as follows:

1) It improves product quality by detecting functional defects early in the manufacturing process.

2) It allows for quick and cost-effective design changes.

3) It saves time by identifying potential issues before products are shipped to customers.

**Classification of FCT Testing**

FCT testing can be categorized based on control modes into:

1) Manual control function test

2) Semi-automatic control function test

3) Fully automatic control function test

Initially, functional testing relied on manual and semi-automatic methods. For some simpler tests, manual or semi-automatic methods are still used to reduce design complexity and production costs. However, technological advancements have led to a shift toward fully automated solutions to further decrease production costs. Another common classification is based on the type of controller used in functionality testing, such as MCU control, embedded CPU control, PC control, or PLC control.

FCT testing is a dynamic function tester that treats the circuit board’s functional unit as a test entity. It provides input signals and detects signals based on design requirements. This approach enhances testing automation with advanced, flexible solutions, significantly reducing fault-finding time and making it the ultimate method for rapid repair and fault diagnosis.

2. This test identifies short and open circuits in the PCB and ensures that the board functions correctly.

3. Additionally, FCT is a crucial step in PCB quality control, typically conducted after the soldering process.

**Advantages of Using FCT Testing on Circuit Boards**

1. Switching testing fixtures enable testing of various FCT function testers. It is a tool used to verify whether a PCBA is qualified. It consists of two parts: the main part and the testing fixture part. The main part includes a computer system and a signal sampling system, which are universal. The testing fixture part has fixed dimensions and is designed with positioning holes for different target test boards. They are connected via flat cables. To test different boards, simply replace the testing fixture and load the corresponding testing program on the computer.

2. Test parameters can be configured: you can adjust, cancel, save new parameters for different frequency conversion boards, and retrieve them as needed.

3. The advantage of functional testing fixtures is that, even with less skilled operators, the same product can be produced efficiently with minimal defects and low variability.

The FCT test, or Functional Circuit Test, includes functions such as voltage and current measurement and control, power factor, frequency and duty cycle, position determination, LED lighting and color, sound recognition, and temperature and pressure measurement.

FCT targets the functionality of each circuit on the board, verifying whether it meets specifications and identifying open or short circuits. It precisely indicates defective parts and their causes. Thus, FCT inspection should be performed after the circuit board plug-in is welded to address issues like input/output testing, power supply voltage and power verification, open and short circuit testing, simulation of signal control boards, and ensuring normal circuit board functionality, dynamic function testing, automatic testing, and overall product quality improvement.

FCT is crucial as it ensures PCB functionality and identifies manufacturing defects before shipping, saving both time and cost.

FCT testing benefits PCB components as follows:

1) It improves product quality by detecting functional defects early in the manufacturing process.

2) It allows for quick and cost-effective design changes.

3) It saves time by identifying potential issues before products are shipped to customers.

**Classification of FCT Testing**

FCT testing can be categorized based on control modes into:

1) Manual control function test

2) Semi-automatic control function test

3) Fully automatic control function test

Initially, functional testing relied on manual and semi-automatic methods. For some simpler tests, manual or semi-automatic methods are still used to reduce design complexity and production costs. However, technological advancements have led to a shift toward fully automated solutions to further decrease production costs. Another common classification is based on the type of controller used in functionality testing, such as MCU control, embedded CPU control, PC control, or PLC control.

FCT testing is a dynamic function tester that treats the circuit board’s functional unit as a test entity. It provides input signals and detects signals based on design requirements. This approach enhances testing automation with advanced, flexible solutions, significantly reducing fault-finding time and making it the ultimate method for rapid repair and fault diagnosis.