Equipment in SMT Production Line

In the SMT production line, various equipment plays a crucial role in producing printed circuit boards. These machines are known for their automation, precision, speed, and efficiency.

Main Production Equipment

- Solder Paste Printers

- Dispensers

- Placement Machines

- Reflow Soldering Machines

- Wave Soldering Machines

Auxiliary Equipment

- AOI Testing Equipment

- X-RAY Equipment

- SPI Equipment

- Rework Stations

- Cleaning Equipment

- Drying Equipment

- Material Storage Systems

Types of SMT Production Lines

SMT production lines are categorized into two main types based on automation:

- Fully Automatic Production Lines: All equipment is fully automated, connected through loading machines and buffer belts.

- Semi-Automatic Production Lines: Main equipment may require manual intervention or loading/unloading.

Classification by Production Scale

PCB production lines vary in size:

- Large Production Lines: High capacity, with general-purpose and high-speed placement machines.

- Small & Medium-Sized Production Lines: Suited for smaller enterprises, accommodating various batch sizes.

Types of Product Lines

Printed circuit board production lines can be:

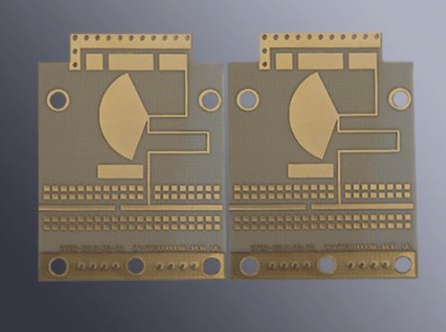

- Single Production Lines: Assemble SMC/SMD products on one side of the PCB.

- Dual Production Lines: Assemble SMC/SMD products on both sides of the PCB.

When looking for SMT patch processing, choose manufacturers based on specific needs and capabilities.