PCB Manufacturing in China: What You Need to Know

1. Complete Turnkey Service or PCB Manufacturing Only

- Consider purchasing PCBs from China? Chinese companies offer complete turnkey services or just manufacturing services. With a complete turnkey assembly, your supplier manages every step, including component procurement.

- If you only need PCB manufacturing services, such as multilayer PCBs or design services, Chinese companies provide affordable options.

2. Advantages of Complete Turnkey Service

- Start-ups and small businesses find complete turnkey services efficient and cost-effective for assembling and testing circuit boards.

3. Import Modules, Purchase Parts

If you encounter issues with your PCB, finding the right part can be challenging. In China, ready-made parts are readily available through experienced channels, addressing procurement and manufacturing challenges effectively.

4. Understanding Capabilities and Services

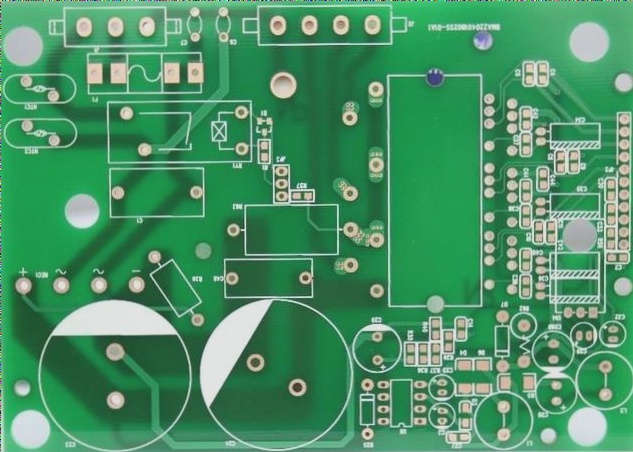

Chinese PCB manufacturers offer multiple solder masks, rapid prototyping, cost-effective mass production, and assembly services. They specialize in precision and large-scale production, providing quick quotations and attractive after-sales services.

5. SMT Template Service

China offers a wide range of Surface Mount Technology (SMT) templates, including frameless, framed, and prototype options. Chinese manufacturers excel in assisting with SMT template services, ensuring reliability and reduced costs.

6. Mode of Transport

Ordering PCBs from China can shorten lead times due to the country’s significant position in the global PCB market. Many engineers prefer working with Chinese companies for their PCB needs.

Reasons to Choose Chinese PCB Manufacturers

The primary reason many individuals and companies opt for Chinese PCB manufacturers is their collaboration with reputable logistics partners like DHL, UPS, and SF Express. This ensures timely delivery of orders.

Shipping and Payment Convenience

Chinese PCB manufacturers not only offer reliable shipping methods but also calculate shipping costs upfront. Moreover, they provide a variety of payment options, including PayPal, credit/debit cards, and direct bank transfers, making transactions convenient for all customers.

Efficient Online Ordering Process

Most Chinese PCB manufacturers cater to overseas customers, streamlining the ordering process for efficiency. By ordering online, customers save time, money, and resources. The process is quick, allowing for easy order tracking until delivery. Inspection certificates and invoices are also provided as needed.

Effective Communication

Chinese PCB manufacturers excel in communication efficiency, offering multiple platforms for customer interaction. Quick responses to inquiries save valuable time and enhance customer experience compared to manufacturers in other countries.

Competitive Pricing and Quality

Chinese PCBs are known for being cost-effective without compromising on quality. Local manufacturers in China adhere to high-quality standards and environmental certifications, ensuring no hidden costs for customers.

Adherence to Regulations

Chinese PCB manufacturers operate under strict laws and regulations, providing legal guarantees for customers’ rights. Clear regulations govern orders during holidays or special occasions, preventing delays and errors in production. Adherence to these regulations ensures reliable communication throughout the manufacturing process.

The Importance of PCBs

PCBs are essential in today’s technological landscape, supporting the development of advanced electronic products and gadgets. When choosing a PCB turnkey service provider, consider factors such as delivery time, price, quality, and safety to meet your production needs in China.