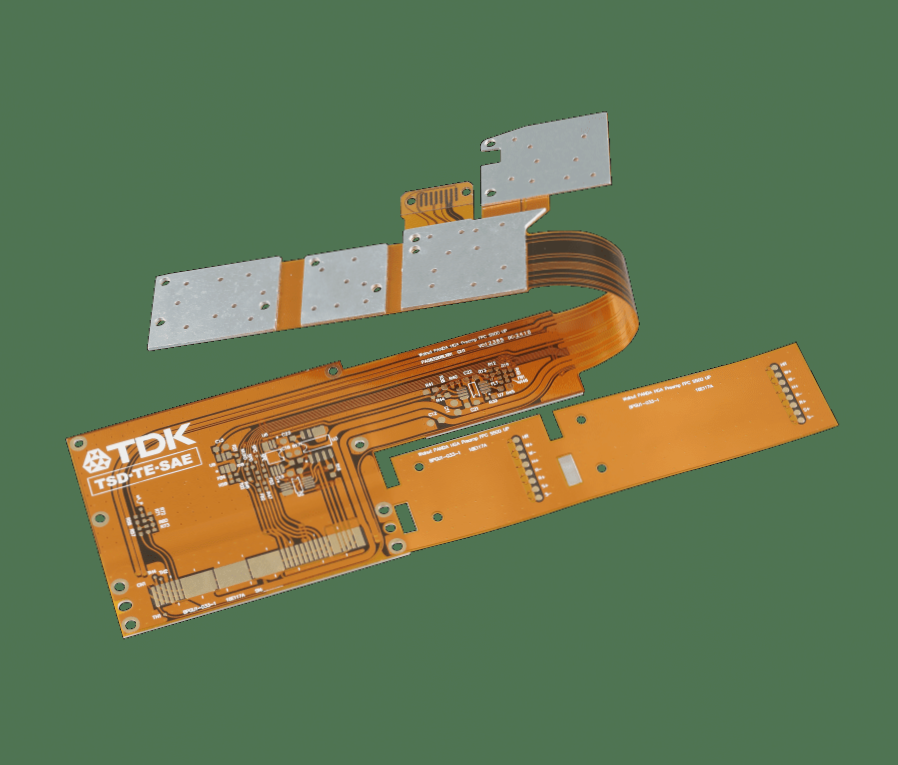

The processing flow of the high-precision eight-layer printed circuit board:

1. Eight-layer copper-clad board blanking

2. drilling benchmark holes

3. CNC drilling through holes

4. inspection

5. deburring

6. brushing

7. electroless plating (through-hole metallization)

8. full-board thin copper plating

9. inspection

10. brushing

11. screen printing of negative circuit patterns

12. Curing (dry film or wet film, exposure, development)

13. inspection

14. repair

15. circuit pattern plating

16. tin electroplating (anti-corrosive nickel/gold)

17. removal of printing material (photosensitive film)

18. copper etching

19. tin stripping

20. cleaning

21. brushing

22. mesh Soldering resist graphics (sticking photosensitive dry film or wet film, exposure, development, thermal curing, commonly used photosensitive thermal curing green oil)

23. cleaning

24. drying

25. screen printing marking character graphics

26. curing-shape processing

27. cleaning

28. drying

29. electrical communication broken inspection

30. spray tin or organic solder mask

31. inspection

32. packaging

33. finished product delivery.

In terms of the process, the high-precision eight-layer PCB undergoes the following steps:

1. Production of printed circuit boards with patterns

2. Acid degreasing

3. Scanning water washing

4. Secondary countercurrent washing

5. Micro-etching

6. Scanning washing

7. Secondary countercurrent washing

8. Copper plating

9. Dipping

10. Copper plating

11. Scanning water washing

12. Tinning prepreg

13. Tinning

14. Secondary countercurrent washing

15. Lower board

For 8 layer PCB, there are via holes and blind holes. The via holes are opened from the top layer to the bottom layer. The blind holes are only visible on the top layer or the bottom layer, and the other layer is invisible, that is, blind holes. The hole is drilled from the surface, but not through all layers. There is also a buried via, which is a via in the inner layer, and the surface and bottom layers are invisible. The advantage of making buried vias and blind vias is to increase the wiring space.

The eight-layer PCB circuit board wiring method involves routing the top layer, the bottom layer, and two middle layers. The top and bottom layers are routed with signal lines. The middle layer first adds INTERNALPLANE1 and INTERNALPLANE2 with ADD PLANE through the command DESIGN/LAYERSTACKMANAGER as the most used power layer such as VCC and ground layer such as GND. Be careful not to use ADD LAYER, this will increase MIDPLAYER, which is mainly used for multi-layer signal line placement. In this way, PLNNE1 and PLANE2 are two layers of copper that connect the power supply VCC and the ground GND.

1. Eight-layer copper-clad board blanking

2. drilling benchmark holes

3. CNC drilling through holes

4. inspection

5. deburring

6. brushing

7. electroless plating (through-hole metallization)

8. full-board thin copper plating

9. inspection

10. brushing

11. screen printing of negative circuit patterns

12. Curing (dry film or wet film, exposure, development)

13. inspection

14. repair

15. circuit pattern plating

16. tin electroplating (anti-corrosive nickel/gold)

17. removal of printing material (photosensitive film)

18. copper etching

19. tin stripping

20. cleaning

21. brushing

22. mesh Soldering resist graphics (sticking photosensitive dry film or wet film, exposure, development, thermal curing, commonly used photosensitive thermal curing green oil)

23. cleaning

24. drying

25. screen printing marking character graphics

26. curing-shape processing

27. cleaning

28. drying

29. electrical communication broken inspection

30. spray tin or organic solder mask

31. inspection

32. packaging

33. finished product delivery.

In terms of the process, the high-precision eight-layer PCB undergoes the following steps:

1. Production of printed circuit boards with patterns

2. Acid degreasing

3. Scanning water washing

4. Secondary countercurrent washing

5. Micro-etching

6. Scanning washing

7. Secondary countercurrent washing

8. Copper plating

9. Dipping

10. Copper plating

11. Scanning water washing

12. Tinning prepreg

13. Tinning

14. Secondary countercurrent washing

15. Lower board

For 8 layer PCB, there are via holes and blind holes. The via holes are opened from the top layer to the bottom layer. The blind holes are only visible on the top layer or the bottom layer, and the other layer is invisible, that is, blind holes. The hole is drilled from the surface, but not through all layers. There is also a buried via, which is a via in the inner layer, and the surface and bottom layers are invisible. The advantage of making buried vias and blind vias is to increase the wiring space.

The eight-layer PCB circuit board wiring method involves routing the top layer, the bottom layer, and two middle layers. The top and bottom layers are routed with signal lines. The middle layer first adds INTERNALPLANE1 and INTERNALPLANE2 with ADD PLANE through the command DESIGN/LAYERSTACKMANAGER as the most used power layer such as VCC and ground layer such as GND. Be careful not to use ADD LAYER, this will increase MIDPLAYER, which is mainly used for multi-layer signal line placement. In this way, PLNNE1 and PLANE2 are two layers of copper that connect the power supply VCC and the ground GND.