Custom Shielding in Electronics: A Vital Solution for Harmful Frequencies

Custom shielding has become a crucial practice in the electrical and PCB manufacturing industry. With the prevalence of digital circuits and semiconductor devices operating at high frequencies, the need for custom shielding to combat harmful electromagnetic waves has never been more essential.

Understanding Custom Shielding and Its Benefits

Custom shielding, also known as circuit board shielding, involves the use of EMI shields (electromagnetic shields) to:

- Minimize the transmission of electromagnetic waves

- Protect sensitive electronic devices from interference

These shields play a significant role in reducing the transmission of electromagnetic and radio frequency waves, safeguarding both the devices and users from potential harm.

Applications of Custom Shields

Various industries rely on custom shielding to ensure the safety and optimal performance of electronic devices, including:

- Medical devices

- Automotive components

- Aviation and aeronautical electronics

- Military devices

- Security devices

- Telecommunication equipment, such as smartphones

- Computer electronics

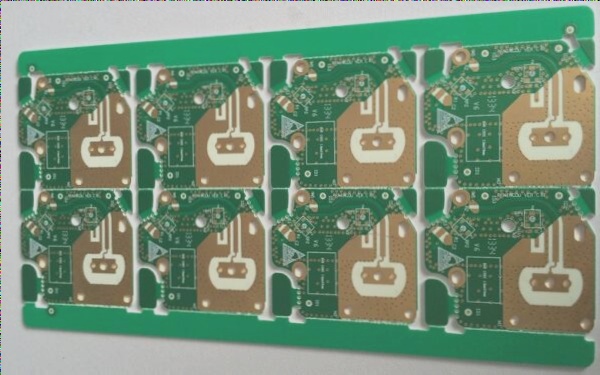

The image above illustrates the internal shields of a dismantled mobile phone, showcasing the implementation of custom shielding in consumer electronics.

Choosing the Right Shielding Material

Choosing the Right Material for PCB Shielding

When finalizing a custom shield for your PCB, it’s crucial to consider the frequencies it needs to block. Excessive shielding can hinder the device’s optimal functionality.

Frequencies emitted by electrical devices vary from a few hertz to 50 GHz. Selecting the appropriate material for shielding is vital as it directly impacts the effectiveness of EMI or RFI shields. Different metals have varying densities, thicknesses, and other properties that influence their shielding capabilities.

Types of Shielding Materials

- Ability to shield frequencies

Manufacturers aiming to shield frequencies up to 15 MHz often use steel due to its ferromagnetic properties and bulk effect, which extends throughout the material.

- Solderability

While metals are excellent for blocking radio and electromagnetic frequencies, not all metals offer the same level of solderability. Choosing metals like pre-tin plated steel ensures effective shielding and easy soldering.

- Weight

Opting for a dense metal can add unnecessary bulk to the shield. It’s essential to choose a metal that is dense yet malleable, such as steel, nickel silver, copper, or brass, to maintain shielding effectiveness without excessive weight.

Standard Base Materials for Shielding

Engineers commonly use three significant metals for custom shield manufacturing:

- Pre-tin plated steel

Steel, especially pre-tin plated steel, is a cost-effective option that can effectively block frequencies up to 15 MHz. It is readily available, easy to work with, and resistant to rust.

- Aluminum

Aluminum is another popular choice for custom shields due to its high conductivity, malleability, and lightweight properties. However, it is prone to corrosion through oxidation and galvanic processes.

- Copper alloy 770

Copper alloy 770, composed of nickel, zinc, and copper, is an excellent option for shielding against electromagnetic and radio frequencies. Its corrosion-resistant properties make it a preferred choice for electronic shielding applications.

Further Reading: Aerospace PCB Assembly

Explore Different Types of Custom Board Shielding:

When it comes to custom board shields, there are various types available to suit different needs. Let’s delve into the main categories:

- One-piece surface mount:

The one-piece surface mount shield is a convenient single-piece attachment option. It offers easy fixing and removal with just one attachment.

There are two variations within this category:

- Two-piece surface mount shielding:

The two-piece surface mount shielding consists of two parts that need to be opened and closed for attachment and detachment.

Within this type, you have two options:

- Low profile slim shields: These shields include a cover piece and a base piece that lock together, providing a low shield height of 0.06 inches. The photo-etching process allows for a wide range of designs at an affordable price.

- Spring finger: This type offers highly configurable two-piece shielding with a unique spring finger design for customization. Shapes like L-shape, rectangular, V-shape, or custom designs can be achieved easily with brass and tin plating components.

3- CBS 2

The CBS 2 shielding features a six-sided custom shield with standard shapes like T, L, rectangle, and square. These shields come with cut-outs for input and output connectivity, effectively sealing ventilation and holes.

PCB Methods

To mitigate harmful waves, it’s crucial to identify frequency sources early. Here are 3 essential steps to detect interference:

1- Use smaller conductor traces between power layers and VCC pins to reduce common-mode interference. Incorporate 4-5 mil pre-peg in circuit layers for effective shielding.

Ensure power layers are close to the bottom layer, allowing signal traces on similar circuit layers.

2- Divide circuit layers into high voltage segments like switch mode supply and bridge rectifiers, and low segments accordingly.

PCB Circuit Design Tips

- Signal conditioner circuits

- Modulation circuits

- High-frequency amplification circuits

- Sensors

When designing PCB circuits, it is important to place the filters of each unit closer to each other to optimize performance.

3- Ensure that traces are placed away from the edge of the PCB and consider the PCB width to reduce resistance. Utilize approximately a hundred thirty-five degrees corner trace for better signal integrity. Keep digital and analog grounds separated.

Advantages of Photo Etched Board Level Shielding

- It is a cost-effective solution for crafting tools.

- Provides greater design flexibility.

- Enables engraving of logos, designs, and symbols inexpensively.

- Allows attachment of pin designs in various configurations.

- Utilizes slots and through holes for heat dissipation without extra cost.

- Offers complex geometry without additional tool expenses.

- Internal dividers are available for multi-cavity applications.

Final Thoughts

Custom shielding in electronic devices is essential for blocking electromagnetic and radio frequency waves effectively. These shields come in various shapes, sizes, fittings, and materials to suit different requirements.