Introduction:

IoT is expected to grow to the rate of $772.5 spent by 2018, with a total increase of 14.6% from the amount spent in 2017. By 2020, annual revenues could exceed $450 for IoT vendors and these figures are expected to keep on growing over time. Today’s market demands implementation of IoT in nearly all electronic products. IoT is helping innovators to invent new tech devices all aiming to appeal to the consumer; the possibilities with IoT are limitless.

IoT devices are not simple; they are a combination of distinct components, interfaces, PCBs and electrical circuits each with a unique design and layout and equal challenges. For modern IoT designs, we require a PCB design environment with advanced functionality. In this article we will discuss the various aspects and critical points to consider when designing PCBs for the Internet of Things.

1: IoT Domains

- Analog & Digital: Analog-to-digital converters (ADC) are used in IoT designing to process, store and transmit analog signals in a digital form to a microprocessor. It basically provides an output which digitally represents the input voltage/current. Analog is advantageous as it offers an infinite number of representations whereas digital has a limited number of possible representations. Analog-to-digital converters help to interfere with the analog world around us.

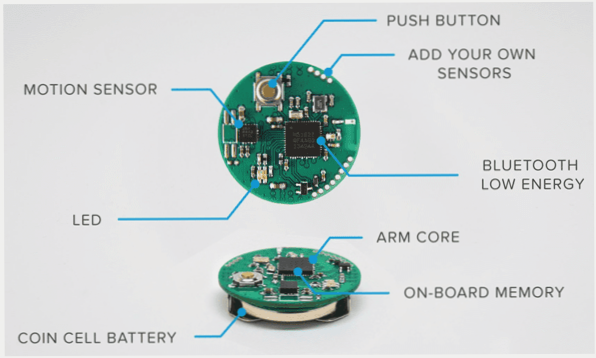

- Micro-electro-mechanical systems (MEMS): MEMS are miniature sensors and actuators which have a widespread use in modern IoT devices. Sensors help to gather information from a device’s surroundings whereas actuators help execute given commands. They are used in fitness trackers and smartphones and are key components in IoT design.

- Radio Frequency (RF): A radio module helps to connect IoT devices to the cloud through Wi-Fi or Bluetooth. For wireless connectivity there are a number of factors to consider including the application requirement, technology constraints, hardware/software integration, power consumption etc.

2: Form and Fit

The design of the device plays a huge role in the human-interface; one might even say a proper design is the driving force for these devices. Human wearables such as fitness trackers should be light and comfortable to the user, smartwatches should be as light as possible, and some products should even fit in aesthetically to appeal to the user. This is why you should always consider starting with a prototype to test its demand in the market, and if it meets the necessary requirements. In some cases the form factor follows the product development, however in other cases, the form factor precedes the product development. For example, IoT wearables shape and size help create the form factor after which the PCB is developed to confirm to the fit.

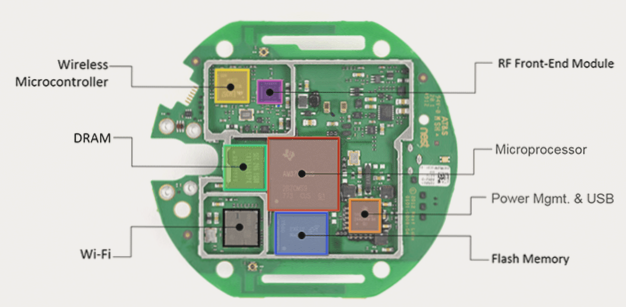

3: IoT Components

IoT devices have a number of integral components which should all be carefully selected before their use. Component selection is critical in regards to functionality and cost both. IoT products also use miniaturized components such as LEDs, cameras, microphones in their design. Buttons, switches, and touch sensors are also common in such devices. Now fingerprint detectors, FSR (force sensing resistors) and flexibility sensors are also coming into use. Many devices such as smartphones and wearables come with batteries and are efficient, while other devices may take use of existing electrical wiring for power such as doorbells, thermostats etc.

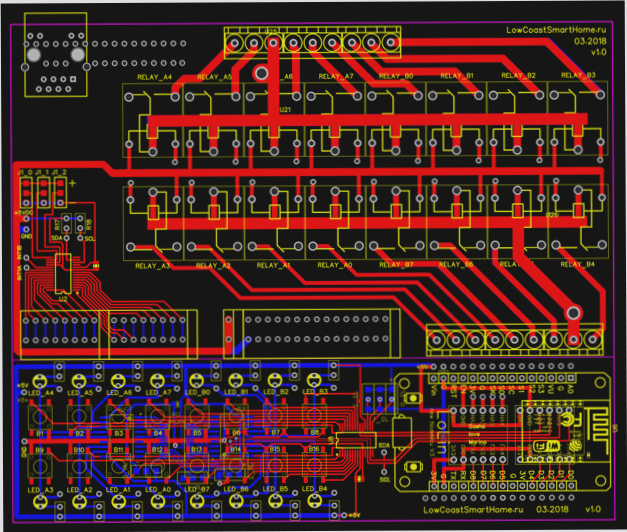

4: Capturing IoT Design Intent

Once the components are selected, the next step is the layout and schematic diagram. Efficiently designing and producing a schematic with properly sourced components can help you manage not only your costs but also give you an efficient product. Direct access to analog/mixed-signal circuit analysis and pre-layout signal integrity analysis from within the schematic design environment is important to help ensure that the designs requirements are achieved.

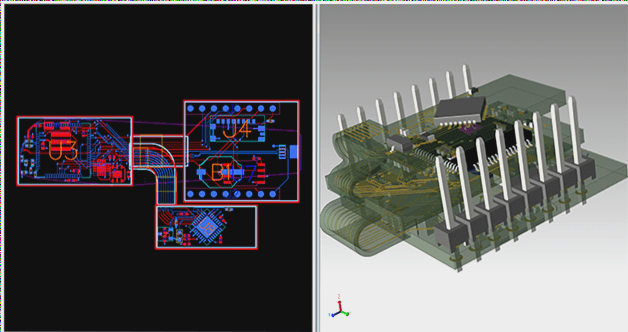

5: Simulation

IoT designs can include analog and mixed-signal (AMS) circuits. You can achieve high performance of AMS circuits through model-based AMS design, simulation and analysis for mixed technology. Verification and optimization of AMS circuits are critical to ensure the design intent, performance and reliability of IoT designs.

6: Validation

IoT devices tend to operate in a number of modes including standby, transmit/receive, active sensing, recharging etc. Therefore, all these various functional modes require individual verification. Pre-layout simulation and planning for post-layout verification is critical for making sure the design meets all the necessary requirements.

7: Power

Wearables form a huge part of the entire IoT market. They are usually small, lightweight and should be power-efficient. Power adjustment can be adjusted from mode to mode to preserve battery life. You should analyze the power integrity during the layout process to prevent any chances of product malfunction or failure due to voltage loss.

8: Memory

IoT products use modern microprocessors which connect to DRAM and flash memory. With IoT designs more detailed simulations are necessary in order to provide a comprehensive view of the memory interface. You can reduce design time and debug cycles of DDR-based designs by accurately routing memory connections.