The Middle Layer in PCB Production

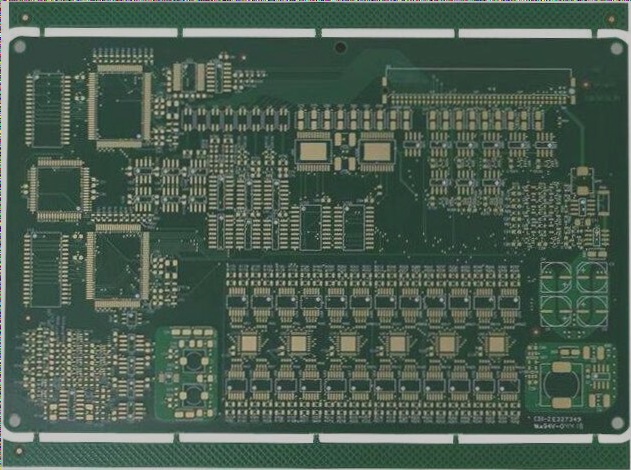

The middle layer in a PCB is crucial for creating multi-layer boards. It acts as a bridge between the top and bottom layers, facilitating easier wiring and enhancing signal isolation and interference resistance.

Creation of the Middle Layer

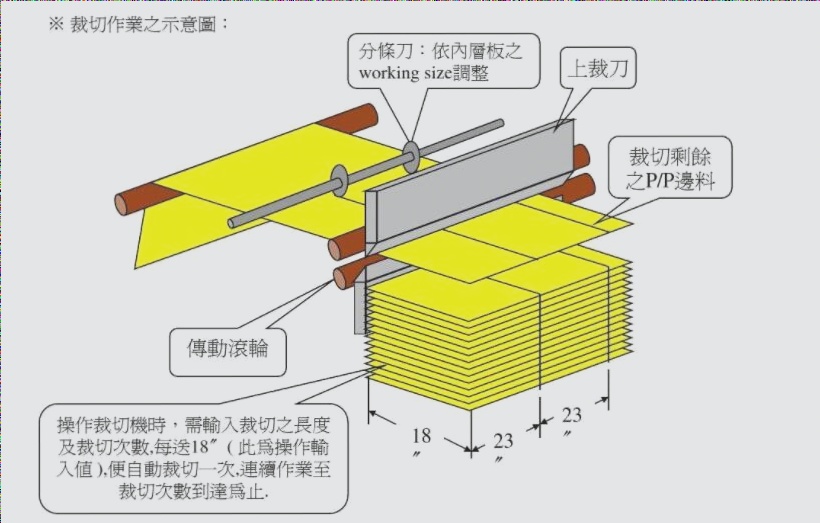

In the PCB production process, the middle layer is realized by pressing together multiple single-layer and double-layer boards. The copper film is first applied to a base material, and wire connections are transferred through processes like photolithography and chemical etching.

- Layer Stack Manager Tool: The Protel system offers a Layer Stack Manager tool for setting and managing layers. Designers can add, modify, and delete working layers, as well as define layer attributes.

- Layer Attributes: The Layer Stack Manager allows designers to set the layer name, copper thickness, and net name for internal electrical layers. Insulating materials like Core and Prepreg provide support and electrical isolation between layers.

- Insulating Layer Thickness: The thickness of the insulating layer affects interlayer withstand voltage and signal coupling. Default values are typically used unless specific requirements dictate otherwise.

Insulating Layer Settings

Insulating layers like Core and Prepreg are essential for PCB construction. Core includes copper films and wires on both sides, while Prepreg is used solely for interlayer isolation. Different stacking modes like Layer Pairs and Internal Layer Pairs determine the pressing methods for creating multi-layer boards.

Benefits of the Middle Layer

The presence of the middle layer makes wiring in multilayer boards easier and enhances signal isolation. It allows for large-area copper connections, reducing line impedance and improving anti-interference performance compared to standard double-layer or single-layer boards.

Layer Stack Manager Operations

- Add Layer: Add an intermediate signal layer between existing layers like GND and Power. Customize properties by double-clicking the layer name.

- Add Plane: Incorporate internal electrical layers below specified locations. Configure properties by double-clicking the layer name.

- Delete: Remove selected layers, excluding top and bottom ones. Confirm deletion by clicking Yes in the dialog box.

- Move Up: Shift the selected layer up by one position without exceeding the top layer.

- Move Down: Shift the selected layer down by one position without going below the bottom layer.

- Properties: Access layer attribute settings for the chosen layer.

Once Layer Stack Manager settings are finalized, click OK to proceed with PCB editing. To view the middle layer in the editing interface, adjust visibility under Internal planes in [Design]/[Options…].

Upon completion, layers will be visible in the PCB editing environment. Toggle between layers by clicking on their labels. Customize colors under [Tools]/[Preferences…] if default settings are not preferred. For more information, refer to Chapter 8.