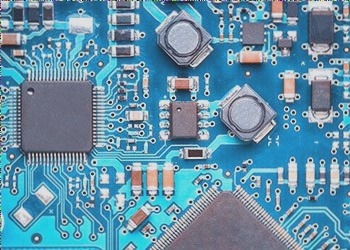

1. An inductor is a common electronic component found in SMT chip technology. Also known as power inductors, high current inductors, and surface mount high power inductors, SMD inductors are characterized by their miniaturization, high quality, high energy storage, and low resistance. They are considered basic electronic components in electronic processing plants.

2. Inductors can be made from a coiled core of conductive material, usually copper wire. The core can also be replaced or removed with a ferromagnetic material. A core material with higher permeability than air can confine the magnetic field more tightly around the inductive element, thus increasing the inductance.

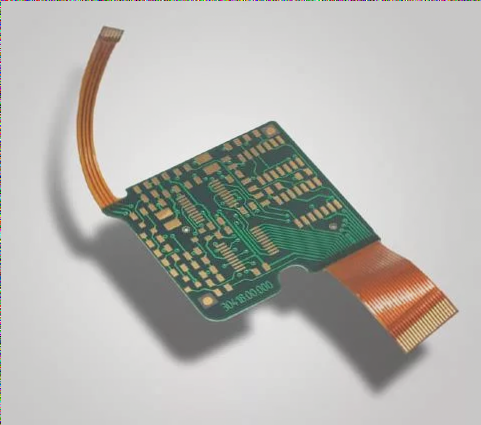

3. There are various kinds of inductors, with most being made of enamel coated wire around a ferrite spool. Some protective inductors encase the coil completely inside the ferrite. The core of certain inductive components can be adjusted to change the inductance. Small inductors can be etched directly on the PCB using a method of laying spiral traces. Small value inductors can also be fabricated in integrated circuits using the same process as that for transistors.

4. Regardless of the method used, a common application based on practical constraints is a circuit called a “rotator,” which uses a capacitive and active element to exhibit the same behavior as an inductive element.

5. When choosing chip inductors in electronic processing, it is important to consider factors such as the operating frequency range and precision of the chip inductors. The total width of the chip inductor and the allowable amount of current are also important factors to consider. Different products use different diameters of magnetic coils, which affects the resistance measurement.

6. When using a power inductor in a DC/DC converter, the size of the inductor will immediately affect the working attitude of the power supply circuit. It is essential to adjust the magnetic coil to achieve the best practical effect.

7. At this stage, there are three common chip inductors: high frequency inductors for microwave heating, high frequency chip inductors for series resonance control loops and frequency selective power supply circuits, and practical inductors generally applicable to power circuits of tens of megahertz. It is important to take these into consideration when selecting the appropriate chip inductor for specific applications.

2. Inductors can be made from a coiled core of conductive material, usually copper wire. The core can also be replaced or removed with a ferromagnetic material. A core material with higher permeability than air can confine the magnetic field more tightly around the inductive element, thus increasing the inductance.

3. There are various kinds of inductors, with most being made of enamel coated wire around a ferrite spool. Some protective inductors encase the coil completely inside the ferrite. The core of certain inductive components can be adjusted to change the inductance. Small inductors can be etched directly on the PCB using a method of laying spiral traces. Small value inductors can also be fabricated in integrated circuits using the same process as that for transistors.

4. Regardless of the method used, a common application based on practical constraints is a circuit called a “rotator,” which uses a capacitive and active element to exhibit the same behavior as an inductive element.

5. When choosing chip inductors in electronic processing, it is important to consider factors such as the operating frequency range and precision of the chip inductors. The total width of the chip inductor and the allowable amount of current are also important factors to consider. Different products use different diameters of magnetic coils, which affects the resistance measurement.

6. When using a power inductor in a DC/DC converter, the size of the inductor will immediately affect the working attitude of the power supply circuit. It is essential to adjust the magnetic coil to achieve the best practical effect.

7. At this stage, there are three common chip inductors: high frequency inductors for microwave heating, high frequency chip inductors for series resonance control loops and frequency selective power supply circuits, and practical inductors generally applicable to power circuits of tens of megahertz. It is important to take these into consideration when selecting the appropriate chip inductor for specific applications.