PCBA labor and materials is a one-stop service, which contains many links, and each link will have an impact on the quality of the final product. Below, WellCircuits Limited will talk about several important nodes in PCBA labor and materials to ensure quality:

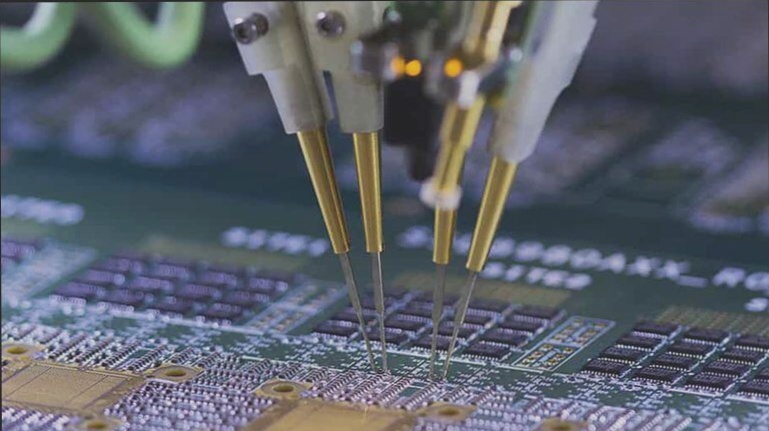

1. SMT patch processing

The details of the systematic quality control of solder paste printing and reflow soldering temperature control in SMT chip processing are key nodes in the PCBA manufacturing process. At the same time, for the printing of high-precision circuit boards with special and complex processes, laser stencils need to be used according to specific conditions to meet higher quality and processing requirements. According to PCB manufacturing requirements and customer product characteristics, some may need to increase U-shaped holes or reduce steel mesh holes. The steel mesh needs to be processed according to the requirements of PCBA processing technology.

Among them, the temperature control accuracy of the reflow oven is very important for the wetting of the solder paste and the firmness of the stencil welding, and can be adjusted according to the normal SOP operation guide. In order to minimize the quality defects of PCBA patch processing in the SMT link. In addition, strict implementation of the AOI test can greatly reduce the defects caused by human factors.

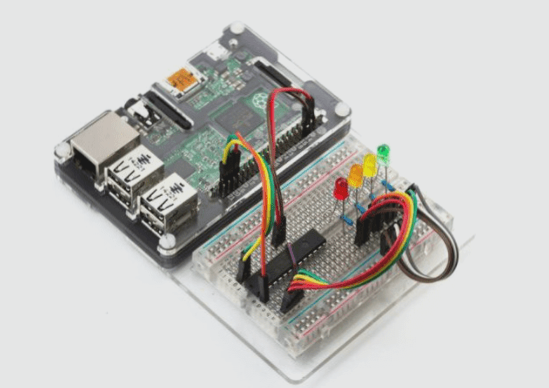

2. DIP plug-in post welding

DIP plug-in post soldering is the most important and final process in the circuit board processing stage. In the process of DIP plug-in post-welding, the consideration of the furnace jig for wave soldering is very important. How to use the furnace fixture to greatly increase the yield rate and reduce soldering defects such as continuous tin, little tin, and tin shortage, and according to the different requirements of customers’ products, PCBA processing plants must continue to summarize experience in practice and accumulate The process achieves technological upgrading.

1. SMT patch processing

The details of the systematic quality control of solder paste printing and reflow soldering temperature control in SMT chip processing are key nodes in the PCBA manufacturing process. At the same time, for the printing of high-precision circuit boards with special and complex processes, laser stencils need to be used according to specific conditions to meet higher quality and processing requirements. According to PCB manufacturing requirements and customer product characteristics, some may need to increase U-shaped holes or reduce steel mesh holes. The steel mesh needs to be processed according to the requirements of PCBA processing technology.

Among them, the temperature control accuracy of the reflow oven is very important for the wetting of the solder paste and the firmness of the stencil welding, and can be adjusted according to the normal SOP operation guide. In order to minimize the quality defects of PCBA patch processing in the SMT link. In addition, strict implementation of the AOI test can greatly reduce the defects caused by human factors.

2. DIP plug-in post welding

DIP plug-in post soldering is the most important and final process in the circuit board processing stage. In the process of DIP plug-in post-welding, the consideration of the furnace jig for wave soldering is very important. How to use the furnace fixture to greatly increase the yield rate and reduce soldering defects such as continuous tin, little tin, and tin shortage, and according to the different requirements of customers’ products, PCBA processing plants must continue to summarize experience in practice and accumulate The process achieves technological upgrading.