1. Since the FPC cable is a type of FPC, its composition mirrors that of traditional FPC.

2. FPC is typically elongated, with both ends designed for pluggable pins, allowing for direct connections to connectors or soldering onto products.

3. The central section usually contains a circuit, and due to the need for flexibility, the base material is commonly rolled copper, which provides excellent resilience and flexibility.

4. The surface treatment process for FPC cables primarily involves gold, though anti-oxidation treatments are sometimes used.

5. However, the anti-oxidation process is less capable of withstanding high temperatures and has lower environmental durability compared to immersion gold, even though their costs are similar.

6. Consequently, immersion gold technology is more widely adopted. Additionally,

There are processes like tin plating and tin spraying; however, the temperature resistance of FPC is typically below 280 degrees Celsius, while the temperature for tin spraying exceeds 300 degrees Celsius. Additionally, the hardness of solder paste is relatively low, making its use uncommon. The cable can move, bend, and twist without damaging the wire, adapting to various shapes and special package sizes. Its only limitation is volume space. Withstanding millions of dynamic bending cycles, this cable is ideally suited for interconnection systems in continuous or regular movement, integrating seamlessly into the final product’s functionality. Solder joints on rigid PCBs face thermal and mechanical stress, often failing after hundreds of cycles. Jenny, EECX’s product manager, noted, “Certain products with smaller form factors/package sizes require electrical signals/power to operate and benefit from flat cables.”

In terms of cost, natural FFC cables are significantly cheaper. Given the production costs, many companies prefer designs related to FFC cables.

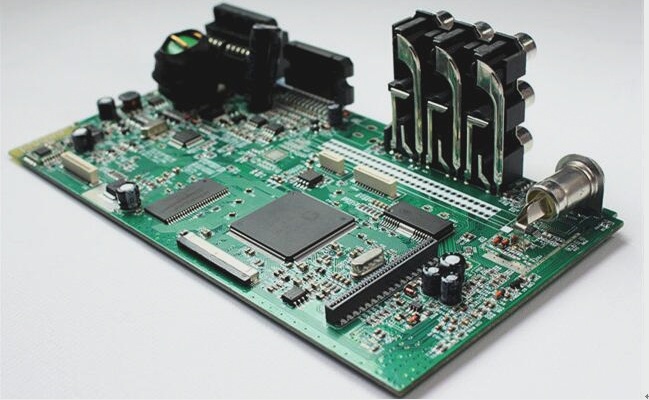

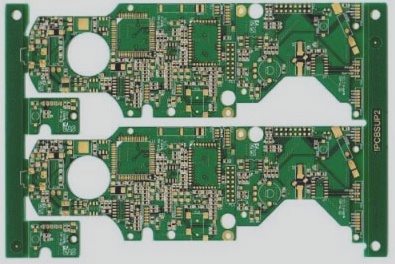

FPC cable metal sheet

Article source: Popularity: 6022 Publication time: 2019-08-14 【Small Zhong Da】

When discussing FPC cables, it’s essential to understand what FPC entails. FPC can be categorized into several types based on function, including FPC antenna, FPC touch screen, and FPC capacitive screen. Among these, FPC cable is one variant. Simply put, FPC cable consists of a set of cables capable of bending to a certain degree.

FPC cable metal sheet

Common specifications include various pitch flexible cables, such as 0.5mm, 0.8mm, 1.0mm, 1.25mm, 1.27mm, 1.5mm, 2.0mm, and 2.54mm. The cable can move, bend, and twist without damaging the wire, accommodating different shapes and package sizes. Its sole limitation is volume space. With the capacity to endure millions of dynamic bending cycles, this cable is well-suited for interconnection systems with continuous or periodic movement, becoming integral to the final product’s functionality. Solder joints on rigid PCBs experience thermal and mechanical stress, typically failing after hundreds of cycles. Jenny, EECX’s product manager, stated, “Electrical signals/power are needed for movement, and flat cables are advantageous for certain products with smaller form factors/package sizes.”

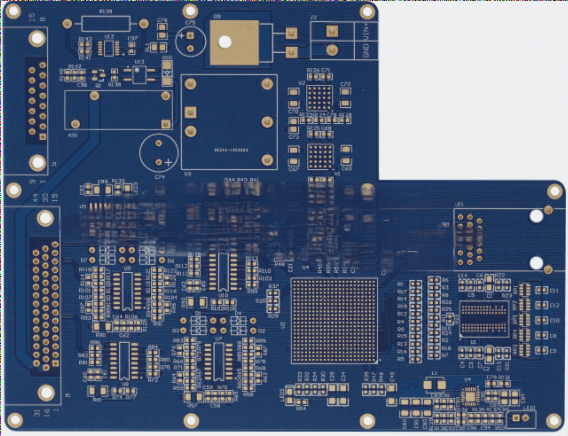

Various reinforcement materials are available for FPC flexible circuit boards, including FR4 reinforcement, PI reinforcement, and steel sheet reinforcement, aimed at ensuring adherence to high-temperature resistance during soldering or adhesive processes.