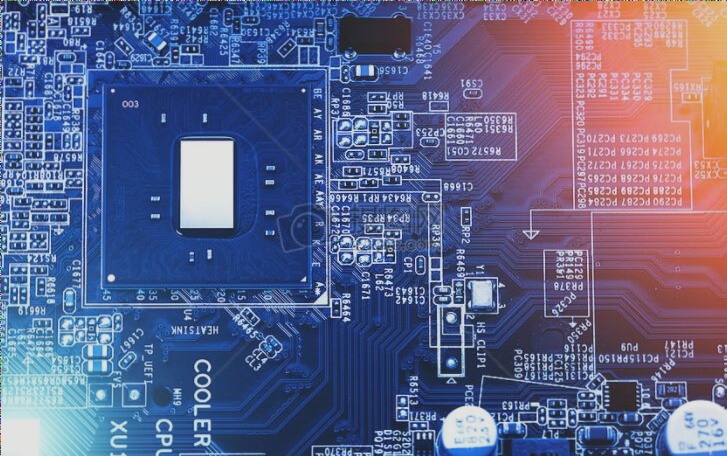

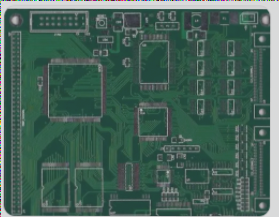

Printed circuit boards must continuously consume various substances in the solution during the electroless copper plating process. According to the production volume, they should be analyzed and tested in time and supplemented to maintain the stability of the solution.

As production continues, the electroless copper plating solution is reused, leading to an accumulation of impurities with frequent additions of chemical substances. It is necessary to replace part of the old solution after a certain production period to enhance the activity of the electroless copper plating solution, ensuring the quality of the electroless copper layer.

After completing the electroless copper plating work, the pH value can be adjusted below 10 using dilute sulfuric acid, and the particulate matter in the solution should be filtered promptly after the reaction stops. When reusing the solution, gradually adjust the pH value within the specified range using dilute alkali under constant stirring.

Ultimately, whether electroless thin copper plating or electroless thick copper plating, it is crucial to prepare the electroless copper plating solution correctly according to process specifications, control process conditions rigorously, maintain the solution carefully, and strengthen both pre-processing and post-processing. These steps are essential for ensuring the final quality of the product.

As production continues, the electroless copper plating solution is reused, leading to an accumulation of impurities with frequent additions of chemical substances. It is necessary to replace part of the old solution after a certain production period to enhance the activity of the electroless copper plating solution, ensuring the quality of the electroless copper layer.

After completing the electroless copper plating work, the pH value can be adjusted below 10 using dilute sulfuric acid, and the particulate matter in the solution should be filtered promptly after the reaction stops. When reusing the solution, gradually adjust the pH value within the specified range using dilute alkali under constant stirring.

Ultimately, whether electroless thin copper plating or electroless thick copper plating, it is crucial to prepare the electroless copper plating solution correctly according to process specifications, control process conditions rigorously, maintain the solution carefully, and strengthen both pre-processing and post-processing. These steps are essential for ensuring the final quality of the product.