I believe that people working in the electronics industry are familiar with circuit boards. Whether you are engaged in software or hardware, you can’t do without circuit boards. However, most people may only have access to ordinary circuit boards and have not seen or even heard of FPC soft boards and Rigid-Flex boards. Now, let’s introduce what FPC soft boards and Rigid-Flex boards are and what their differences are from ordinary circuit boards, as well as what we should pay attention to when designing PCBs.

FPC soft boards and Rigid-Flex boards also belong to a category of circuit boards, which are only used in special cases. Before introducing the FPC soft board and Rigid-Flex combination board, let’s first understand what a circuit board is.

Circuit boards can be divided into various types such as ceramic circuit boards, alumina ceramic circuit boards, aluminum nitride ceramic circuit boards, PCB boards, aluminum substrates, high-frequency boards, thick copper boards, impedance boards, ultra-thin circuit boards, and printed circuit boards (copper etching technology). They can be found in any electronic equipment and play a role in fixing and connecting electronic devices in the circuit.

Next, let’s introduce what FPC soft boards are.

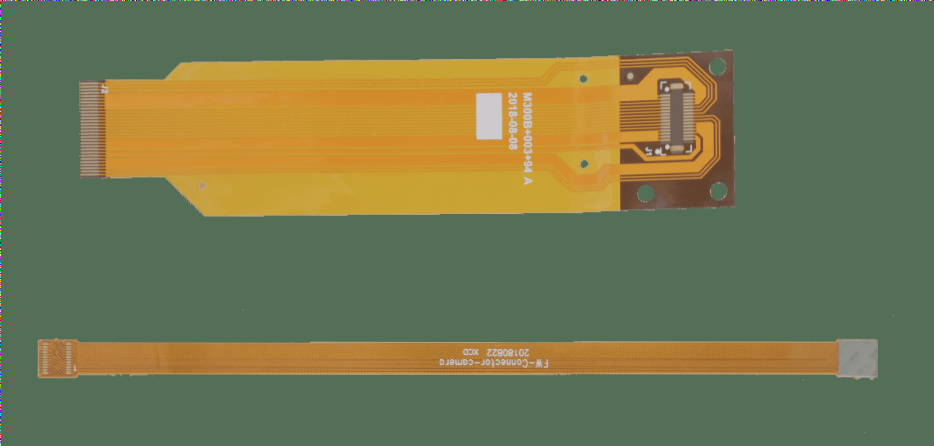

FPC circuit board, also known as FPC flexible circuit board, is a highly reliable and excellent flexible printed circuit board made of polyimide or polyester film. It has the characteristics of high wiring density, lightweight, thin thickness and good bending, and is mainly used for connecting with other circuit boards. FPC soft board can save the internal space of electronic products to a certain extent, making the assembly and processing of products more flexible. For example, LCD/OLED and AMOLED screen display panels in smartphones are connected through FPC soft boards and are widely used in notebook computers, digital cameras, medical, automotive, aerospace and other fields.

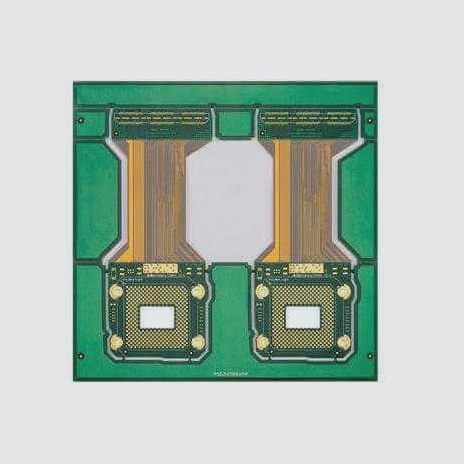

After we understand the soft board, it is easy to understand the soft and hard combination board. As the name implies, the soft and hard combination board refers to the flexible circuit board and the hard circuit board, which are combined according to the relevant process requirements after pressing and other processes to form a circuit board with FPC characteristics and PCB characteristics.

The soft and hard bonding plate has the characteristics of FPC and PCB at the same time. Therefore, it can be used in some products with special requirements, including certain flexible and rigid areas. It is very helpful to save the internal space of the product, reduce the volume of finished products, and improve the performance of the product. However, the soft and hard bonding plate is difficult to produce and has a low yield, so its price is relatively expensive and the production cycle is relatively long.

After we know what FPC soft board and soft hard combination board are, what should we pay attention to in the actual design?

Note:

1. The device needs to be placed in the hard area and the flexible area is only used for connection, which can improve the life of the board and ensure its reliability of the board. If the device is placed in a flexible area, it is easy to cause the bonding pad to crack or the characters to fall off.

2. When the device is placed in the hard area, it shall be at least 1mm away from the soft and hard areas.

When wiring:

1. The distance between the soft area pattern and the board edge shall be at least 10mil, and no holes shall be punched. The distance between the through the hole and the soft and hard joint shall be at least 2mm.

2. The lines in the soft board area should be smooth, and the corners should be connected by arc routing. At the same time, the straight line and arc should be vertical. The pad needs to be treated with teardrops to avoid tearing.

3. At the edge of the flexure area, copper foil shall be used to reinforce the connection at the bending point of the connecting line.

4. In order to achieve better flexibility, the bending area should avoid the change in line width and uneven line density.

5. The wiring at the bottom of the table shall be staggered as far as possible to avoid overlapping lines at the bottom of the table.

Now let’s introduce what FPC soft boards and soft-hard boards are, and what their differences are from ordinary Rigid-Flex Board circuit boards, and what we should pay attention to when designing PCBs.

FPC soft boards and Rigid-Flex boards also belong to a category of circuit boards, which are only used in special cases. Before introducing the FPC soft board and Rigid-Flex combination board, let’s first understand what a circuit board is.

Circuit boards can be divided into various types such as ceramic circuit boards, alumina ceramic circuit boards, aluminum nitride ceramic circuit boards, PCB boards, aluminum substrates, high-frequency boards, thick copper boards, impedance boards, ultra-thin circuit boards, and printed circuit boards (copper etching technology). They can be found in any electronic equipment and play a role in fixing and connecting electronic devices in the circuit.

Next, let’s introduce what FPC soft boards are.

FPC circuit board, also known as FPC flexible circuit board, is a highly reliable and excellent flexible printed circuit board made of polyimide or polyester film. It has the characteristics of high wiring density, lightweight, thin thickness and good bending, and is mainly used for connecting with other circuit boards. FPC soft board can save the internal space of electronic products to a certain extent, making the assembly and processing of products more flexible. For example, LCD/OLED and AMOLED screen display panels in smartphones are connected through FPC soft boards and are widely used in notebook computers, digital cameras, medical, automotive, aerospace and other fields.

After we understand the soft board, it is easy to understand the soft and hard combination board. As the name implies, the soft and hard combination board refers to the flexible circuit board and the hard circuit board, which are combined according to the relevant process requirements after pressing and other processes to form a circuit board with FPC characteristics and PCB characteristics.

The soft and hard bonding plate has the characteristics of FPC and PCB at the same time. Therefore, it can be used in some products with special requirements, including certain flexible and rigid areas. It is very helpful to save the internal space of the product, reduce the volume of finished products, and improve the performance of the product. However, the soft and hard bonding plate is difficult to produce and has a low yield, so its price is relatively expensive and the production cycle is relatively long.

After we know what FPC soft board and soft hard combination board are, what should we pay attention to in the actual design?

Note:

1. The device needs to be placed in the hard area and the flexible area is only used for connection, which can improve the life of the board and ensure its reliability of the board. If the device is placed in a flexible area, it is easy to cause the bonding pad to crack or the characters to fall off.

2. When the device is placed in the hard area, it shall be at least 1mm away from the soft and hard areas.

When wiring:

1. The distance between the soft area pattern and the board edge shall be at least 10mil, and no holes shall be punched. The distance between the through the hole and the soft and hard joint shall be at least 2mm.

2. The lines in the soft board area should be smooth, and the corners should be connected by arc routing. At the same time, the straight line and arc should be vertical. The pad needs to be treated with teardrops to avoid tearing.

3. At the edge of the flexure area, copper foil shall be used to reinforce the connection at the bending point of the connecting line.

4. In order to achieve better flexibility, the bending area should avoid the change in line width and uneven line density.

5. The wiring at the bottom of the table shall be staggered as far as possible to avoid overlapping lines at the bottom of the table.

Now let’s introduce what FPC soft boards and soft-hard boards are, and what their differences are from ordinary Rigid-Flex Board circuit boards, and what we should pay attention to when designing PCBs.