The Essential Principles of Multi-layer PCB Layout and Routing

-

Setting Trace Spacing for Components

When designing a PCB, it is crucial to consider the spacing between different networks for components. Factors like electrical insulation, manufacturing processes, and component sizes play a significant role in determining the appropriate spacing. For instance, maintaining a specific design rule, such as a 6 mil spacing for chip components with an 8 mil pin pitch, is essential. Additionally, ensuring adequate electrical insulation between components with varying voltage levels is critical to prevent interference or shorts.

-

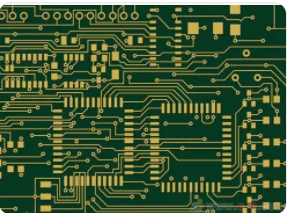

Choosing Wiring Forms at Line Corners

During PCB design, selecting the right cornering style for circuit corners is vital for both manufacturability and aesthetics. Options like 45° turns, 90° angles, or curved corners can impact signal integrity. Avoiding sharp corners and using smooth transitions, such as arc turns, is recommended to prevent reliability issues. Techniques like teardropping can help create smoother transitions between traces and pads.

-

Determining Trace Width

Trace width selection is influenced by factors like current flow and EMI control requirements. Power traces should typically be wider than signal traces to accommodate higher currents. Maintaining stable ground potential may require wider trace widths for ground lines. Experimentally, a 0.05mm thick trace can carry 1A of current per mm of width. For high-voltage or high-current applications, wider trace widths may be necessary to ensure safe current carrying capacity.

-

EMI Protection and Shielding

Minimizing electromagnetic interference (EMI) is crucial for PCB performance. Effective routing, grounding strategies, and proper layout can significantly reduce interference sources like crosstalk and power line interference. Enhancing electromagnetic compatibility (EMC) through strategic design practices can improve overall PCB performance.

Maximizing Trace Width for High-Frequency Signals

When dealing with high-frequency or sensitive signal traces, such as clock signals, it is crucial to maximize the trace width to minimize signal loss and interference. By increasing the trace width, you can reduce the resistance and inductance of the trace, allowing the signal to propagate more efficiently.

Implementing Grounded Shielding for Signal Integrity

Employing a ground layer that surrounds the signal trace can greatly improve signal integrity. This grounded shielding technique effectively isolates the signal trace from neighboring traces, reducing the chances of crosstalk and interference. By creating a continuous ground path or adding a dedicated shield layer around the trace, you can enhance the performance of your PCB design.

Reducing Interference with Grounded Shielding

Grounded shielding is a proven method to reduce interference from adjacent signal traces. By creating a barrier between the signal trace and other traces, you can maintain signal integrity and minimize the risk of signal distortion. This technique is especially beneficial for high-speed digital circuits where signal quality is critical.

Looking for PCB Manufacturing Services?

If you are in need of PCB manufacturing services that prioritize signal integrity and performance, feel free to reach out to us. Our team of experts is dedicated to providing high-quality PCB solutions tailored to your specific requirements.