When you manufacture or use printed circuit boards (PCBs) in your projects, you need to make sure they work well and keep your customers happy. To do so, it is essential to have a reliable way to test PCBs, ensuring that they work as intended. There are many ways to test PCB and below will be the TOP 6 most effective ways to test PCB Assembly today.

PCB is a non-conductive and multi-layer printed circuit board in which all the electronic components are connected on the circuit board and have a base underneath.

PCB boards are used to mechanically support and electrically connect electronic components using electrical leads or signal traces etched from laminated copper sheets onto a non-conductive substrate.

To ensure that the PCB board works efficiently, the PCB inspection is indispensable. Here are the TOP 4 tests that manufacturers should not ignore:

1. Automated X-ray Inspection (AXI)

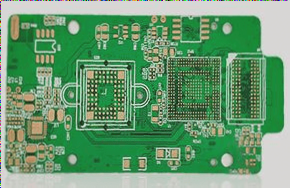

Automated X-ray inspection (AXI) is applied to inspect PCBs containing components with array-type packaging or high-pitched packaging including BGA, CGA (Column Grid Array), CSP (Chip Size Package), etc. The AXI is usually placed during assembly, right after the last weld.

Furthermore, Automated X-ray Inspection is often applied together with boundary scan, ICT, and functional testing to obtain optimal inspection results. AXI uses X-rays instead of light imaging to inspect PCBs. Companies often use AXI to evaluate tables that are particularly complex or densely designed.

Advantages of AXI in PCB inspection include: Some defects can be found in the early stages of printed circuit board assembly; contribute to the reduction of the cost of defects; prevent defects caused by flooding during PCB assembly or even actual customer projects.

However, AXI is a new, complex technology, and its main drawback is cost. Because AXI is very expensive, it is generally not worth using except with particularly complex or highly clustered tables.

2. Automatic laser test measurement (ALT)

Automated laser inspection (ALT) measurement uses a laser instead of traditional light imaging for PCB inspection (specifically, scanning and measuring PCBs ).

As light from the laser reflects off the PCB components, the ALT system uses the position of the laser to precisely determine the position and height of the various components and assess their reflectivity. The ALT system can compare experimental measurements with a diagram or set of specifications to detect any errors.

The ALT measurement is particularly useful in assessing solder position and quantity, although interference can sometimes make the measurement inaccurate.

3. Product Appearance Inspection (AOI)

Product appearance inspection (AOI-Automated optical inspection) is an automated visual inspection of the PCB (or LCD, transistor) circuit board manufacturing process in which the camera automatically scans the device under inspection to look for both critical (e.g. missing ingredients) and quality defects (e.g. fillet size or shape or ingredient deviation).

This is a non-contact test method that is performed at multiple stages through the manufacturing process including bare board inspection, solder paste (SPI) test, and preheat reheat…

To check the PCB condition, the AOI System captures a series of images using a high-resolution camera with LED illumination for automatic comparison or a laser scanner with micrometer resolution in the X, Y axis, and Z.

The type of test being conducted determines which system is used. For example, a solder paste tester will use laser scanning to determine solder mass on the pad, while an assembly verification system focuses on images of solder components.

The benefits that AOI brings can be mentioned as:

- Make sure your PCB products work as intended

- Can check complex board designs with high accuracy

- Quickly detect errors in the PCB manufacturing process immediately

- AOI is an automated process, but the operator can set parameters to tell the scanner what to check.

However, the AOI system will also have some disadvantages as follows:

- AOI only catches PCB errors and does not catch errors with hard-to-classify error modes such as glue or seal errors.

- Defect detection is not flexible, each change must be programmed.

- AOI does not detect new detections, it only detects pre-programmed errors.

- Teams do not have access to data from the AOI system.

4. In-Circuit Test (ICT)

In-Circuit Test (ICT) in circuit board technology is an acronym for In-Circuit Test. It is also known as the in-circuit test.

Structurally, it is an example of white box testing, where an electrical probe checks a printed circuit board and checks for errors like shorting, opening, etc. Ideally, you could do this test with a foundation-type test fixture or an in-circuit test alignment that does not feature.

This type of test method works by checking for PCB failures that may occur during the repair of components on the board. In doing so, you can easily replace any defective parts. Furthermore, it provides a quick and simple way to evaluate the board’s production process and provides accurate results. ICT can also use suction cups to test chip strength and toughness.

Although the in-circuit test is a very powerful tool for PCB testing, it has the following limitations:

Parallel components can usually only be tested as a single component if the components are of the same type (i.e. two resistors)

Electrolytic components can only be tested for polarity in specific configurations (e.g. if not connected in parallel to the power rail) or with a specific sensor

The quality of the electrical contacts cannot be tested unless additional test points and/or specialized auxiliary cable harnesses are provided.

If no testing access is provided by the PCB designer then some tests will not be possible.

Solder defects in circuit board assemblies can include shorts between nets, poor solder joints, or insufficient solder. Many times, these problems can be detected by various detection techniques, starting with manual inspection by a technician.

However, for close inspection, PCB manufacturers will use automated optical inspection equipment (AOI). These systems use high-power optics to scan the board and compare the results to known good boards.

Why AOI systems are used in testing for pcb assembly?

AOI systems are used for pre-installation solder paste inspection, solder joint inspection, and to verify that the correct components are installed on the board.

Manufacturers will use x-ray systems to conduct more detailed inspections of these components, such as large BGA parts, which have solder joints hidden beneath them. Assembly Verification

Manufacturers will use automated test systems to test and verify assembled circuit boards, including circuit tests (ICT), flying probes, and cable scanning.

ICT and flying probe tests rely on probe tips touching small test points on the board to test each net on the board. ICT systems use test fixtures and test probes to quickly test each test point on the board simultaneously.

The flying probe system maneuvers a small number of probes around the board to test each test point individually. The cable scans all the connectors plugged into the board to test the network through their connections.

5. Function Test for PCB Assembly

In addition to assembly verification testing, PCB manufacturers can also perform functional testing of the board. Functional testing is designed to simulate the operational behavior of a power supply when it is turned on, allowing the test operator to determine whether it is properly manufactured to its specifications.

However, without the right design criteria for testability, the testing process can run into some big problems, and we’ll discuss the next steps.

Lack of test strategy:

In order for manufacturers to adequately test boards, a prepared test strategy is required. This means providing not only functional test specifications for the board but also a complete documentation package. Documentation should include schematics, artwork files, bill of materials, and netlist files for the design.

Insufficient test point coverage:

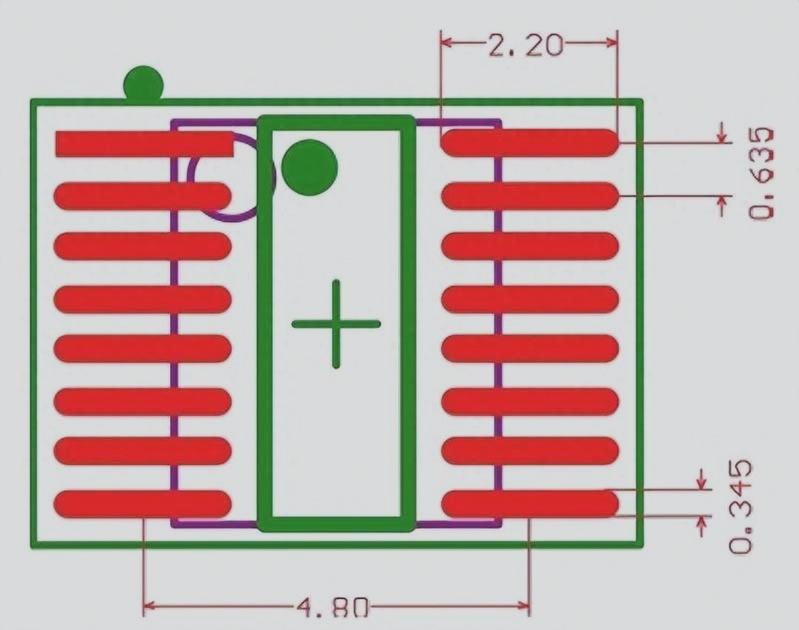

The board must have complete test point coverage for ICT or flying probe testing, which means that every active net must be connected to a test point. Test points can be dedicated design objects such as surface mount pads, or test points can be assigned to existing through-hole pins or vias.

6. Insufficient spacing of test points:

Access each test point that must place the automatic test probes with sufficient spacing. 50 mils are typically used for gaps between test points and other design objects, such as component outlines or pads, while 100 mils are used for gaps between test points and the edge of the board.

Manually test unavailable probe points:

Manually test the probe points that a technician needs to access for network debugging or functional testing.

These probing points are usually pads or holes that are required for the test points and, in some cases, short pins inserted to clamp the probes. Probe points should be clearly marked on a wire mesh, the grid indicating that they are representative and providing sufficient clearance for easy access.

Missing or incorrect or outdated versions of test fixtures:

ICT requires a potentially expensive test fixture to build or modify. While the ability to quickly test thousands of production boards costs, a limited run of new fixtures will slow down test times while increasing costs.

Altering existing test fixtures to make board changes can also be expensive, and these changes need to be carefully weighed to prevent fixture modifications. For low-volume production or prototyping, a different test program is often a better choice.

Outdated components

Using old components can cause problems for test engineers performing functional tests on the board. Components may not produce the expected results, making it harder to verify that the board meets its specifications. A better solution, in this case, is to use a PCB contract manufacturer to find newer components or circuit changes. Your PCB CM can help you make many design decisions to support a good PCB test strategy.