### Circuit Board Edge Stamp Hole Design

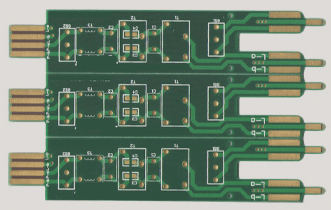

1. Generally, V-cut scoring or routing techniques are employed in the design of circuit boards. In addition to these two methods, a stamp hole design approach is also available.

2. The term “stamp hole” is used because this PCB design resembles the perforated stamps commonly seen. Small holes are placed strategically on the board to facilitate the use of tools like pliers for dividing the board, or users can simply break the connecting ribs between the holes by hand to achieve board separation.

3. The primary advantage of the “stamp hole” method is that it does not require any specialized tools for separation, unlike the other two methods that necessitate specific scoring and routing machines. However, this stamp hole technique does come with several drawbacks, which are outlined below:

4. After dividing the board at the stamp holes, it is common to encounter burrs and uneven edges. These burrs can sometimes lead to assembly issues; for instance, areas where displays are mounted must be free from contaminants like burrs. Moreover, uneven edges can cause assembly interference and may even lead to functional problems.

5. Standard splitting tools are typically not employed for separating stamp holes. If the force applied during separation is not properly managed, it can easily result in bending of the circuit board, leading to solder cracks or damage to components, among other quality concerns.

▪ Due to the uncertainty surrounding the stamp hole splitting tool, achieving a stable manufacturing process is challenging, making PCB quality hard to control. This type of stamp hole is typically utilized in circuit boards where V-cut cannot be employed due to its inherent limitations. If the cut board is inadequately designed, it may fail to support weight, leading to deformation. Ultimately, we must revert to stamp hole design, which is a topic of interest in some academic institutions. Poor designs can easily result in burrs that hinder assembly, often necessitating additional processing that is time-consuming, labor-intensive, and unwelcome.

The following presents two distinct stamp hole designs. Can you identify the differences? Both feature five small 1.0mm diameter stamp holes, yet the outcomes are markedly different. The PCB with the inferior stamp hole design leads to residue after board separation, with burrs extending beyond the molding line. For precision products, these burrs typically require extra manpower for post-processing and smoothing, resulting in wasted labor and increased costs, alongside the risk of dust contamination affecting other products.

The core difference between the two stamp hole designs lies in the positioning of the ribs. In the superior design, the rib edges align perfectly with the centers of the adjacent stamp holes, facilitating pre-formed holes that make it easier to break the edge of the board and reduce the likelihood of burrs extending beyond the molding line post-separation.

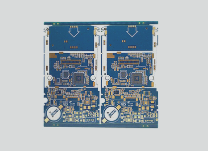

Poorly designed circuit board [stamp hole]

In this design, burrs generated after board separation extend beyond the molding line, necessitating manual post-processing for smoothing, which not only wastes manpower and man-hours but also raises costs. Additionally, the debris produced during grinding poses a contamination risk to other products. (The image on the left depicts a three-hole stamp hole design, yet the results remain consistent.)

Better-designed circuit board [stamp hole]

This design proves superior. Although some burrs remain after the PCB is divided, nearly all can be leveled within the molding line, preventing assembly interference.

1. Generally, V-cut scoring or routing techniques are employed in the design of circuit boards. In addition to these two methods, a stamp hole design approach is also available.

2. The term “stamp hole” is used because this PCB design resembles the perforated stamps commonly seen. Small holes are placed strategically on the board to facilitate the use of tools like pliers for dividing the board, or users can simply break the connecting ribs between the holes by hand to achieve board separation.

3. The primary advantage of the “stamp hole” method is that it does not require any specialized tools for separation, unlike the other two methods that necessitate specific scoring and routing machines. However, this stamp hole technique does come with several drawbacks, which are outlined below:

4. After dividing the board at the stamp holes, it is common to encounter burrs and uneven edges. These burrs can sometimes lead to assembly issues; for instance, areas where displays are mounted must be free from contaminants like burrs. Moreover, uneven edges can cause assembly interference and may even lead to functional problems.

5. Standard splitting tools are typically not employed for separating stamp holes. If the force applied during separation is not properly managed, it can easily result in bending of the circuit board, leading to solder cracks or damage to components, among other quality concerns.

▪ Due to the uncertainty surrounding the stamp hole splitting tool, achieving a stable manufacturing process is challenging, making PCB quality hard to control. This type of stamp hole is typically utilized in circuit boards where V-cut cannot be employed due to its inherent limitations. If the cut board is inadequately designed, it may fail to support weight, leading to deformation. Ultimately, we must revert to stamp hole design, which is a topic of interest in some academic institutions. Poor designs can easily result in burrs that hinder assembly, often necessitating additional processing that is time-consuming, labor-intensive, and unwelcome.

The following presents two distinct stamp hole designs. Can you identify the differences? Both feature five small 1.0mm diameter stamp holes, yet the outcomes are markedly different. The PCB with the inferior stamp hole design leads to residue after board separation, with burrs extending beyond the molding line. For precision products, these burrs typically require extra manpower for post-processing and smoothing, resulting in wasted labor and increased costs, alongside the risk of dust contamination affecting other products.

The core difference between the two stamp hole designs lies in the positioning of the ribs. In the superior design, the rib edges align perfectly with the centers of the adjacent stamp holes, facilitating pre-formed holes that make it easier to break the edge of the board and reduce the likelihood of burrs extending beyond the molding line post-separation.

Poorly designed circuit board [stamp hole]

In this design, burrs generated after board separation extend beyond the molding line, necessitating manual post-processing for smoothing, which not only wastes manpower and man-hours but also raises costs. Additionally, the debris produced during grinding poses a contamination risk to other products. (The image on the left depicts a three-hole stamp hole design, yet the results remain consistent.)

Better-designed circuit board [stamp hole]

This design proves superior. Although some burrs remain after the PCB is divided, nearly all can be leveled within the molding line, preventing assembly interference.