Mastering the Art of PCB Design and Production

Designing and producing a PCB board involves translating a schematic into a physical board, a process that requires attention to detail and precision. While creating a PCB board may not be inherently difficult, ensuring its quality is a different story altogether.

Key Challenges in Microelectronics

Processing high-frequency signals and weak signals are two major challenges in microelectronics, making the level of PCB production crucial. Different individuals can produce PCB boards with varying characteristics even with the same design and components.

Insights for High-Quality PCB Production

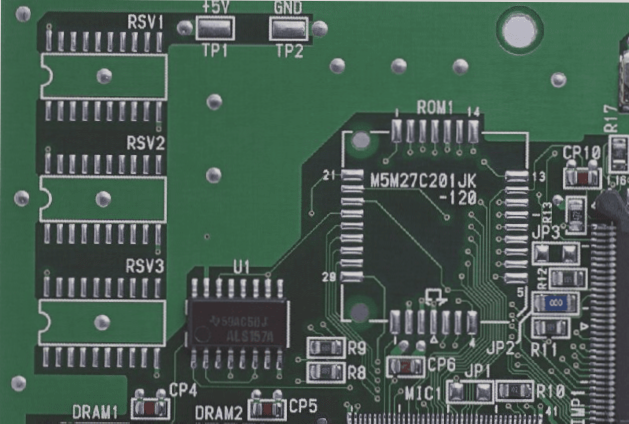

- Be clear about your design goals: Understanding the specific requirements of your PCB design, whether it involves high-frequency signals, weak signals, or a combination of both, is essential. Factors like layout, wiring, signal lines, and heat dissipation need careful consideration.

- Understand the layout and routing requirements: Special components may have unique layout and wiring needs. For example, analog signal amplifiers require stable power supply and separation from power devices.

- Component layout considerations: Placing components related to wiring together, separating power and small signal devices, and ensuring neat placement for testing convenience are crucial.

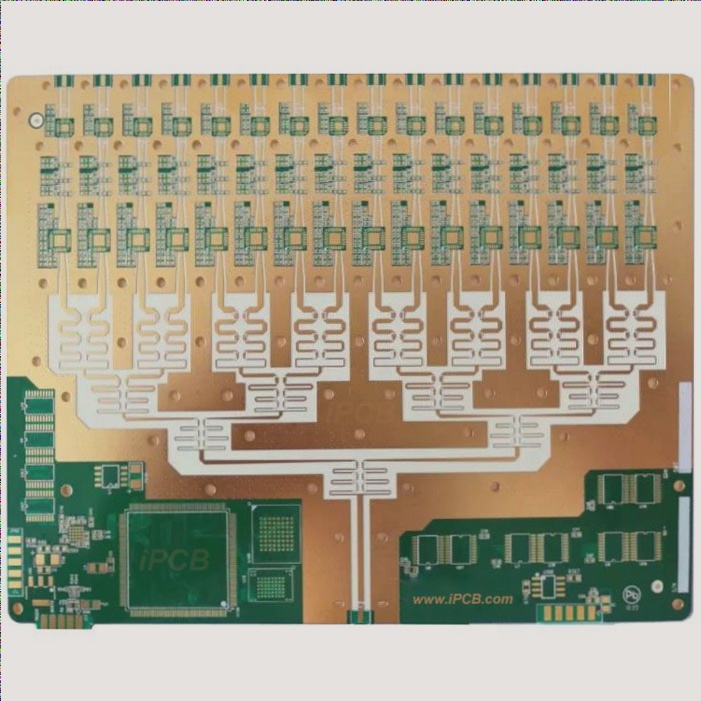

- Considerations for wiring: With the rise of high-speed signal lines, maintaining signal integrity becomes paramount. Shortening trace lengths and implementing line impedance matching are essential for high-speed circuits.

Types of Transmission Lines

As technology advances, various types of transmission lines are being used in PCB design to ensure efficient signal transmission and integrity.

Types of Transmission Lines

- Coaxial Cable

- Twisted Pair

- Microstrip Line

- Striplines

Transmission lines come in various types with different characteristic impedances and propagation delay times per unit length. Understanding the termination methods is crucial for optimal performance.

Termination Methods

There are two main termination methods:

- Parallel Termination

- Series Termination

Series termination allows the circuit to drive parallel load lines effectively and control crosstalk. On the other hand, parallel termination distributes the load along the line without affecting the drive gate delay time. Designers choose the termination method based on their preferences and system requirements.