The Evolution of PCB Design and Manufacturing

The continuous development of the direct plating process in printed circuit board (PCB) design has been fueled by the need to accommodate the miniaturization of components. From through-hole components to surface-mounted devices, PCB designs have evolved to support more pins and smaller components. This evolution has led to an increase in PCB layers, thicker circuit boards, and smaller via holes.

Addressing High Aspect Ratio Challenges

To tackle challenges related to high aspect ratios, production line specifications now incorporate improvements in solution movement and micro-hole exchange. Techniques like using ultrasonic technology to quickly wet holes and remove bubbles have become essential. Additionally, the use of air knives and dryers plays a critical role in effectively drying thick circuits and small holes on the board.

The Rise of HDI Technology

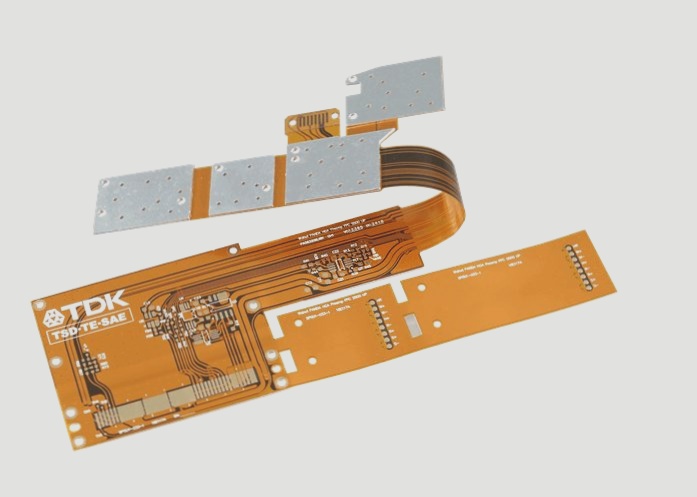

With the shift towards Ball Grid Array (BGA) and Chip Scale Packages (CSP) with finer grids, micro-blind vias have become crucial in High-Density Interconnect (HDI) technology. Designers now leverage micro-blind vias to address challenges like blind hole starvation, pin count, and ball grid density.

Ongoing Developments in PCB Manufacturing

PCB manufacturers are constantly adapting to emerging trends in technology to stay competitive in the industry. Two key areas of development include:

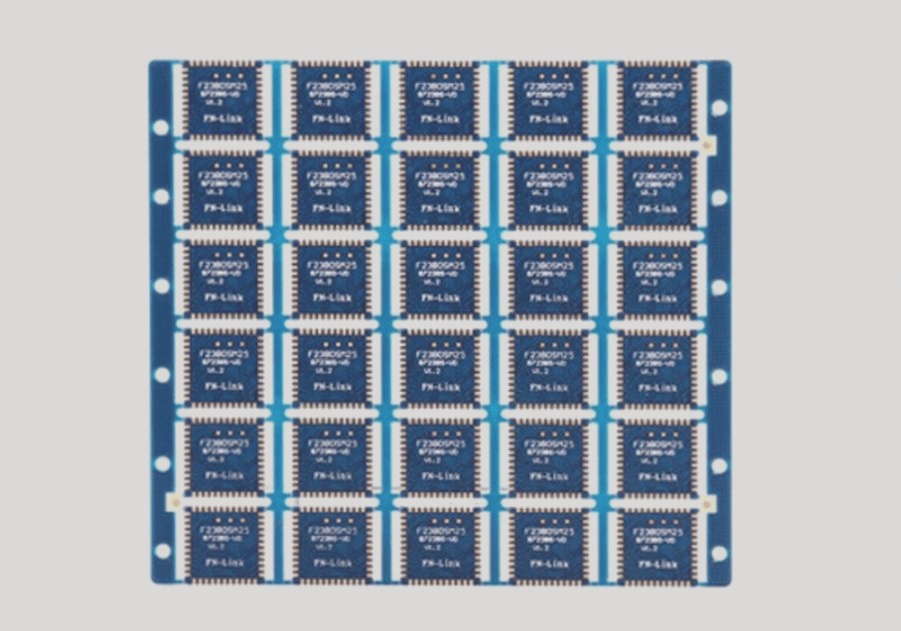

- Component Embedding Technology: Manufacturers are integrating semiconductor and electronic components into the inner layers of PCBs. This technology presents challenges in analog design methods, production techniques, and quality inspection, emphasizing the need for reliability and increased investment in resources.

- Advancements in HDI Technology: HDI technology continues to drive innovation in mobile phone development and PCB technology. It enables thinner traces, smaller openings, and the development of template substrates for packaging. The application of HDI technology in terminal electronics sets the stage for future advancements.

Future Trends and Innovations

Technologies like 5G, biometrics, and autonomous driving are expected to influence the development of circuit boards, cloud storage, computing, and base stations. This progression towards smart factories signifies a new era in PCB technology.

Expert PCB Services

For all your PCB and PCBA needs, look no further than our team of professionals. With years of experience and a commitment to quality, we are here to help you with any questions or concerns you may have.

Feel free to reach out to us at info@wellcircuits.com for personalized assistance tailored to your specific requirements.