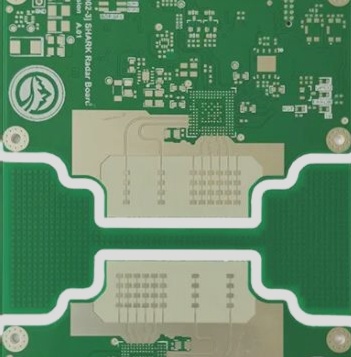

Printed Circuit Boards (PCBs) in Network and Communication Applications

PCBs are essential components in various industries, especially in network and communication sectors. These boards play a vital role in ensuring smooth communication processes. The selection of materials for PCBs is a crucial first step in the design process, impacting the board’s overall performance significantly. Designers must consider various factors to align material properties with specific application requirements.

Challenges in PCB Manufacturing

One common challenge in PCB manufacturing is the reliance on material data sheets by designers. While these sheets offer valuable insights into the material’s electrical properties, real-world manufacturing issues often go beyond these specifications. Addressing practical manufacturing challenges is essential to ensure high-quality outputs and cost-effectiveness.

Materials Used in PCBs

- 370HR: PCBs made with 370HR prepreg and laminate are resistant to Conductive Anodic Filament (CAF), a common issue in PCBs. These boards offer high-density interconnects, excellent thermal reliability, and superior CAF resistance, making them ideal for network and communication applications.

- Glass Epoxy FR4: This versatile high-pressure thermosetting laminate provides excellent electrical insulation and mechanical properties, making it suitable for network and communication applications.

- High-Speed Pyralux TK: Used primarily in high-frequency PCB applications, these materials offer strong electrical insulation, low moisture absorption, and enhanced flexibility, ideal for demanding environments.

- Polyimide: Known for its exceptional thermal stability, polyimide is a cost-effective choice for network and communication PCBs, offering reliable surface mounting capabilities.

Important PCB Material Properties

- Coefficient of Thermal Expansion (CTE): CTE refers to the rate of expansion of PCB materials when heated. Managing CTE is crucial to prevent interconnection issues, especially when the material exceeds its glass transition temperature (Tg).

- Dielectric Constant (Dk) or Relative Permeability (Er): Dk is the ratio of a material’s dielectric constant to that of free space. Understanding Dk values is essential for selecting materials suitable for specific applications, with higher Dk materials commonly used in microwave applications.

High-Speed PCB Materials for Communication Network Equipment

As communication network equipment evolves towards high-speed systems, the demand for PCB materials with exceptional electrical properties is on the rise. At the same time, cost optimization plays a vital role in improving the competitiveness of electronic products. Therefore, PCB designers in the communication network industry are faced with the challenge of choosing materials that offer a balance between high electrical performance and cost-effectiveness.