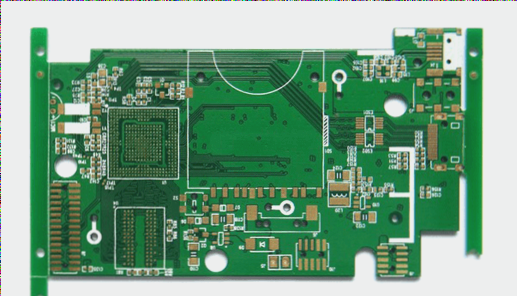

Understanding PCB Colors and Materials

Exploring the Impact of Color and Coatings on PCB Performance

When it comes to PCBs, the choice of color and materials plays a crucial role in both aesthetics and functionality. Traditionally, black PCBs have been associated with high-end products, while colors like red and yellow are often seen as more budget-friendly options. However, the color of a PCB is primarily determined by the solder resist paint used during the manufacturing process, rather than indicating quality or performance differences.

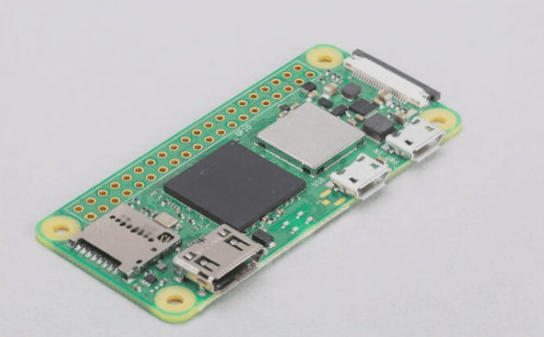

The Role of Solder Resist Coating

- Copper oxidation is a common issue in PCBs without proper protection.

- Solder resist coating acts as a barrier, preventing oxidation and ensuring optimal electrical conductivity.

- Engineers have started using colored solder resist paints to enhance aesthetics and ease of maintenance.

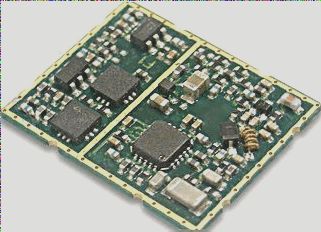

Gold and Silver Plating on PCBs

- Gold and silver plating on PCBs are often touted as superior options.

- These precious metal coatings protect exposed copper pads from oxidation during soldering.

- Manufacturers conduct rigorous oxidation testing to ensure PCBs remain free from performance issues.

While the color of a PCB may influence its appearance, it does not impact its overall quality or functionality. By understanding the role of coatings and materials like gold and silver, users can make informed decisions when selecting PCBs for their projects.