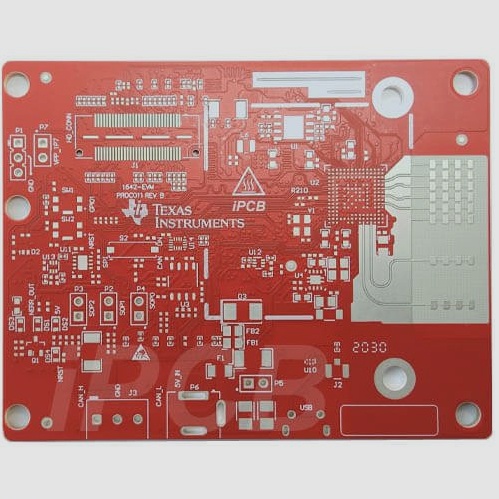

Types of PCB Surface Finishes: Enhancing Durability and Performance

A printed circuit board (PCB) acts as a vital link between electronic components and devices, undergoing multiple processes to ensure functionality. One crucial aspect is the PCB surface finish, which protects the board from external damage and corrosion. Let’s explore the significance of different types of PCB surface finishes to meet your specific requirements.

Importance of PCB Surface Finish

PCB surface finish plays a critical role in facilitating smooth electrical conductivity across copper-based PCBs, safeguarding delicate components from damage, oxidation, and corrosion. With a range of surface finish options available, users can choose based on factors like budget, environmental conditions, reliability, and reworkability.

Types of PCB Surface Finishes

- Hot Air Solder Leveling (HASL): Cost-effective and widely used, suitable for through-hole or larger SMT components.

- Lead-free HASL: Utilizes alloys like Copper-Tin, Nickel-Tin, or Copper-Tin-Nickel Germanium, recommended for PCBs with smaller components.

- Immersion Tin (ISn): Ideal for flat, backplanes, press-fit, and fine pitch products, cost-effective compared to other finishes.

- Immersion Silver (IAg): RoHS compliant, suitable for fine pitch applications, requires OSP protection.

- Electroless Nickel Immersion Gold (ENIG): Popular for its robustness and longevity, provides excellent protection and reliability.

Choosing the Right Surface Finish

Selecting the appropriate PCB surface finish is crucial for the performance and longevity of your PCB. Consider consulting a professional PCB fabricator to determine the most suitable and cost-effective solution for your specific needs.

For more information on PCB fabrication, visit: PCB Fabrication