DIP Packaging Technology in PCB Assembly

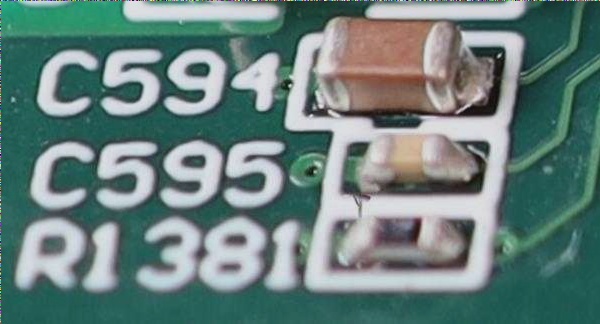

DIP, or Dual In-line Packaging, is a method used to package circuit boards and create integrated circuits. This technology is commonly used for small-scale integrated circuits with fewer than 100 pins. The CPU pins are directly inserted into corresponding holes on the circuit board, which is then inserted into a DIP socket.

Handling DIP-Packaged Chips

When plugging and unplugging DIP-packaged chips, it is important to handle them with care as the pins are fragile and prone to breakage.

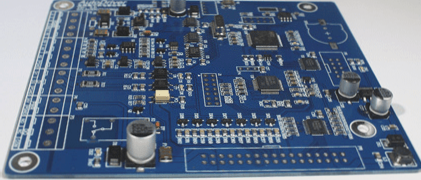

The Rise of Surface Mount Technology (SMT)

Surface Mount Technology (SMT) is rapidly advancing and there is a trend towards replacing DIP technology. However, DIP plug-in units are still essential in certain specialized components during the PCB assembly process.

Significance of DIP Technology

Despite the automation of SMT, DIP technology continues to play a significant role in PCB assembly, albeit requiring more manual labor.

- PCBA manufacturing process