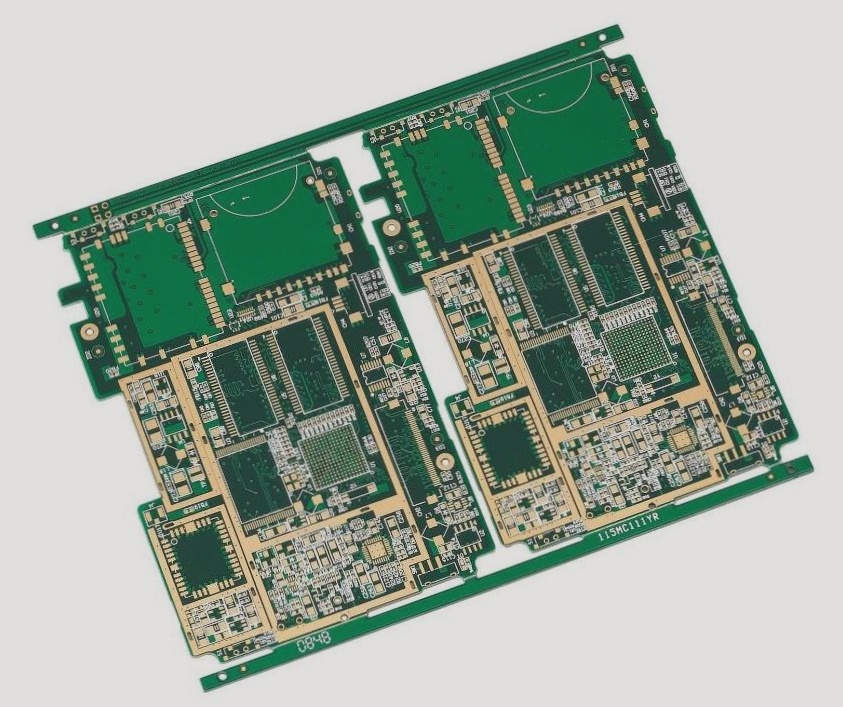

Rapid Manufacturing Methods for High-Precision PCB Circuits

In the fast-paced world of electronic communication technology, traditional circuit board manufacturing methods struggle to keep up with the demands of today’s rapidly evolving era. The need for quick production of high-precision, high-performance, and cost-effective PCB circuits poses a significant challenge for circuit design engineers.

1. Rapid Circuit Board Manufacturing Techniques

- Physical Method: This involves manually removing unwanted copper layers from circuit boards using various cutting and power tools.

- Chemical Method: A protective layer is applied to a copper-clad laminate, and excess copper is etched off using a corrosive solution. This method, widely used today, offers various approaches for applying the protective layer:

Methods for Applying Protective Layer:

- Hand Painting: Circuit designs are manually drawn on copper-clad laminates using brushes or hard pens, followed by etching.

- Adhesive Stickers: Stickers are applied to the board to create the desired circuit pattern before etching.

- Photosensitive Film: Circuit designs are printed on a film, transferred to the laminate coated with photosensitive material, and etched after processing.

- Thermal Transfer Printing: Circuit designs are directly printed onto the board using a thermal transfer printer before etching.

2. Pros and Cons of Rapid Circuit Board Production Methods

Physical Method: Labor-intensive with low accuracy, suitable for simple designs but limited by skill requirements and time constraints.

Chemical Method: Offers controllable precision but comes with challenges:

- Printing Accuracy: Dependent on printer cartridge precision, affecting circuit quality.

- Exposure and Development Time: Requires precise control and experimentation for optimal results.

- Corrosion Process Control: Demands professional equipment and expertise for consistent quality.

- Environmental Requirements: Darkroom conditions and proper storage for photosensitive plates.

- Toxicity Concerns: Handling toxic materials during the process and waste disposal pose risks.

- Manual Processing: Post-etching manual work may affect accuracy, especially with hole punching.

As the demand for precise and fast circuit board production rises in various industries, circuit design engineers must hone their skills and expertise to meet these challenges effectively.