1. The charge will accumulate on the bipolar plate of the capacitor in the PCB design.

2. A capacitor with a capacitance of C, designed for PCB, is represented by a constant current intensity I.

3. It is assumed that the capacitor in the PCB design is initially uncharged, meaning the initial voltage across the capacitor is zero.

4. We recall the definition of current: the amount of charge passing through the cross-section of a conductor per unit time is termed current intensity, which is present in the capacitor designed by the PCB.

5. Therefore, the amount of charge flowing through the cross-section of the conductor per unit time is called current intensity. This is the current intensity.

6. The capacitance of the PCB design is denoted by C. Under the influence of constant current intensity I, the voltage V across the capacitor increases linearly with time.

7. The higher the voltage across the capacitor in the PCB design, the more charge it contains, resulting in greater energy storage.

8. However, the resistance of the insulating medium between the two plates of the capacitor is limited.

9. If the electric field strength between the plates becomes too high, the insulating medium may break down, causing the capacitor to short-circuit.

10. Therefore, in practical applications, it is essential to balance the voltage and resistance of the capacitors in PCB design.

11. Conclusion: The capacitor designed for PCB serves the purpose of storing electric charge in the circuit, thus functioning as an energy storage device.

12. The PCB capacitor can retain energy for an extended period and cannot alter the voltage across its terminals.

13. The larger the capacitance of the PCB design, the more energy it can store.

14. Capacitance and voltage resistance are the two most critical parameters in PCB design.

15. The RC charging and discharging circuit is represented by the RC charging and discharging circuit.

16. Assuming the initial voltage across the capacitor in the PCB design is zero and switch K is connected, the power supply charges the capacitor through resistor R.

17. The maximum charging current of the capacitor is E/R. If charging continues with this current, the rising curve of VC will be a straight line.

18. However, due to the charging current throughout the process, as VC increases, the charging current intensity IC gradually decreases, while VC rises until it reaches the power supply voltage E, at which point the charging current becomes zero.

19. This forms the actual VC rising curve, which is exponential over time t and is expressed as follows:

20. Here, we define the time constant.

21. It can be observed that the larger the series resistance R, the smaller the charging current, leading to a longer charging time; conversely, the larger the capacitance C of the PCB design, the more power is required (i.e., more energy stored), resulting in a longer charging time.

22. When the capacitor in the PCB design is fully charged, VC equals E.

23. When switch K is activated, the discharge current of the capacitor after resistor R gradually decreases over time.

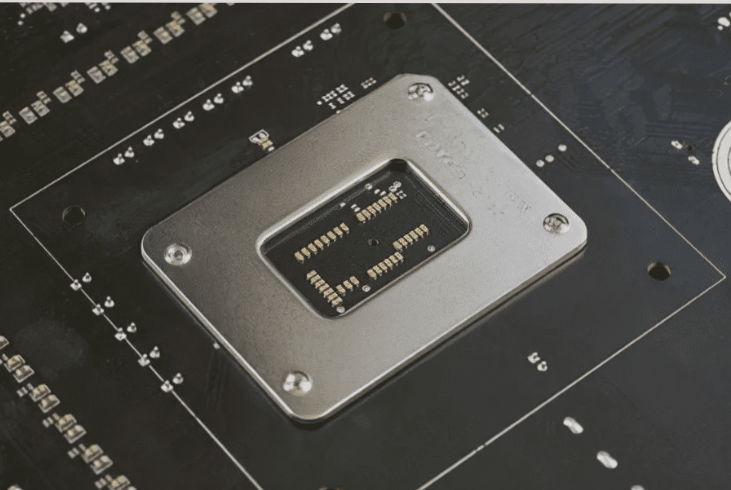

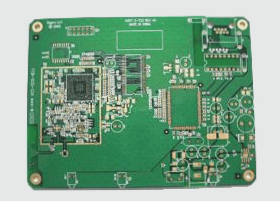

24. The optimized layout of the internal electronic components in the PCB design, including metal connections, vias, electromagnetic protection, heat dissipation, and other factors, along with excellent layout design, can reduce production costs and enhance circuit performance and thermal management.