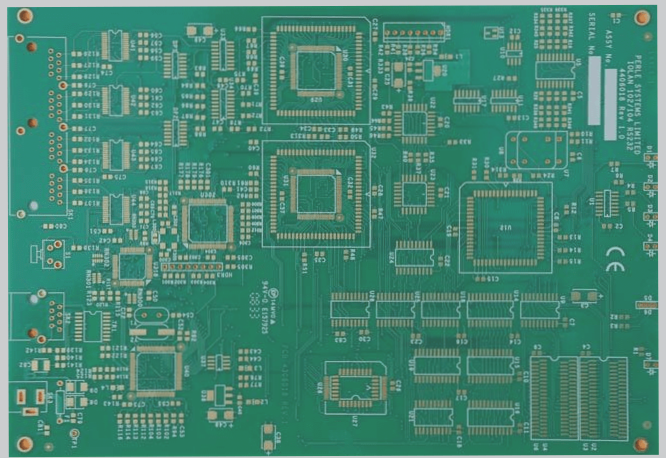

Halogen-Free Substrate: What You Need to Know

Halogen-free PCB substrates are defined as copper-clad laminates containing minimal amounts of chlorine (Cl) and bromine (Br). Examples of halogen-free materials include TUC’s TU883, Isola’s DE156, and the GreenSpeed series.

Reasons to Avoid Halogens in PCBs

Halogens like chlorine, bromine, and iodine can be harmful when present in PCB materials. Halogen-containing flame-retardant materials release toxic substances when burned, impacting health and the environment. Legislation now prohibits the use of certain halogen compounds in electronic products.

Instead of traditional halogen-based materials, halogen-free substrates use phosphorus and nitrogen compounds for flame retardancy. These compounds produce incombustible gases when burned, enhancing the material’s safety.

Benefits of Halogen-Free Sheets

- Low Water Absorption: Halogen-free sheets have lower water absorption due to their nitrogen-phosphorus oxygen reduction resin composition, improving material reliability.

- Enhanced Thermal Stability: Higher nitrogen and phosphorus content in halogen-free sheets results in improved thermal stability and lower coefficient of thermal expansion compared to halogen-containing materials.

Switching to halogen-free materials offers distinct advantages in terms of insulation resistance, breakdown resistance, and overall reliability, making it a growing trend in the PCB industry.

Laminating Parameters for PCB Manufacturing

When laminating PCBs using Shengyi substrates and PP in multi-layer boards, it is crucial to ensure full resin flow and strong bonding. This can be achieved by employing a lower heating rate (1.0-1.5°C/min) and multi-stage pressure fitting. A longer high-temperature stage of over 50 minutes at 180°C is recommended for optimal results. The bonding strength between the copper foil and the extruded board substrate should be 1.0N/mm, with no delamination or air bubbles observed after six thermal shocks.

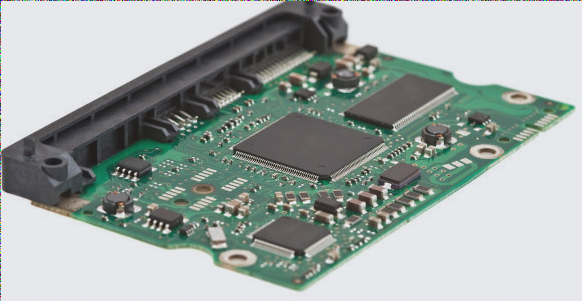

Drilling Process Considerations

Drilling conditions play a vital role in maintaining the quality of the hole wall during PCB processing. Halogen-free copper-clad laminates, known for their higher molecular weight and stronger molecular bond rigidity due to P and N functional groups, require special attention during the drilling process. The Tg of halogen-free materials is typically higher than that of conventional laminates, necessitating adjustments to standard drilling parameters for satisfactory results.

Alkali Resistance and Etching

Halogen-free PCB sheets generally exhibit lower alkali resistance compared to standard FR-4 materials. Therefore, caution must be exercised during the etching process and rework after applying solder masks. Controlling the immersion time in alkaline stripping solutions is crucial to prevent white spots from forming on the substrate.

Halogen-Free Solder Mask Production

The global market offers a variety of halogen-free solder mask inks that perform comparably to traditional liquid photosensitive inks. The production process for halogen-free solder masks mirrors that of conventional inks. Halogen-free PCBs, with low water absorption and compliance with environmental standards, are increasingly sought after for their quality and eco-friendly properties.