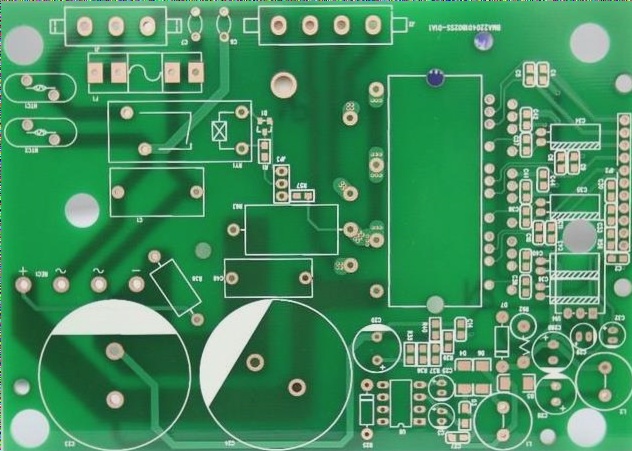

Manual Soldering and Rework Tools for PCB Boards

Hand soldering and rework on PCB boards require skilled operators and quality tools. Surface mount soldering can be more challenging than through-hole soldering due to smaller pin pitch and higher pin count. During rework, care must be taken to avoid overheating the board, which can damage plated through holes and pads.

- Contact Welding: Involves the heated tip or ring making direct contact with the solder joint. Different designs include single nozzle welding tools, welding nozzles, and soldering iron rings for various applications.

- Heated Gas Welding: Another common type of hand welding that requires precision and control to avoid damage to components.

- Thermostatic Systems: Provide continuous heat output for surface mount applications in the 335~365°C temperature range.

- Temperature-Limiting Systems: Help maintain temperature within a specific range, delivering heat discontinuously to prevent overheating.

Features of Contact Welding Systems

- Cost-Effective: An easy method for repair welding and component removal.

- Efficient: Elements attached with glue can be easily removed using welding rings.

- Availability: Contact welding equipment is relatively inexpensive and readily available.

However, challenges may arise with components like plastic pin chip carriers, where ensuring all pins are heated simultaneously can be difficult. Regular maintenance, cleaning, and proper temperature control are essential for the longevity and effectiveness of soldering tools.

Thermal shocks from improper soldering techniques can damage ceramic components, particularly multilayer capacitors. Operators must ensure proper contact and temperature control to prevent such issues.

Hot Air Soldering

- Hot air soldering is achieved by directing heated air or an inert gas, like nitrogen, at solder joints and pins using a nozzle.

- Equipment options range from simple hand-held units for single-location heating to complex automated designs for multiple locations.

- Hot air systems avoid localized thermal stresses, making them ideal for applications where uniform heating is crucial.

- The temperature range for hot air is typically 300~400°C, with larger components requiring longer heating times.

- Nozzle design is critical, directing hot air towards solder joints and away from component bodies.

- Characteristics include controlled temperature, controllable heating rates, and reduced thermal shock.

- Issues with hot air systems involve equipment costs, complexity of automatic systems, and proper flux and solder usage.

Side Etching

- Side etching refers to the sidewall etching of wires under a resist pattern, with the degree represented by the width of the side etch.

- The etching coefficient is the ratio of wire thickness to side etching, with a higher coefficient indicating less side etching.

- Coating widening occurs during pattern electroplating, where the width of the wire increases due to the thickness of the electroplated metal layer.

- Coating edge is the sum of coating widening and side erosion, with the goal of minimizing coating widening in production.

- Etching rate measures how quickly an etching solution dissolves metal, while dissolved copper amount indicates the copper-dissolving ability of the solution.

Reasons for Lack of Tin in Electroplated Nickel-Gold PCB Plating

-

Pre-Plating Treatment:

Ensure proper acid degreasing to remove any surface impurities. Adjust degreasing agent concentration/temperature and pay attention to micro-etching depth and board color uniformity.

-

Nickel Plating Issues:

If nickel cylinder is polluted, recommend low-current electrolysis or carbon core filtration. Adjust pH with dilute sulfuric acid or nickel carbonate. Check nickel plating thickness and porosity, monitor current density, and conduct metallographic sectioning if necessary.

-

Gold Plating Problems:

Ensure proper washing of nickel layer to prevent false gold plating. Control washing time and use hot pure water. Dry PCB promptly in a well-ventilated area post-washing.

-

Post-Processing:

After washing, dry PCB promptly in a well-ventilated area outside the electroplating workshop. Use high-quality cleaning water to avoid city/tap water with high hardness or containing complex organics.

Attention should be given to all chemical treatments, with a focus on water quality for cleaning processes. Avoid using city water, recycled water, or lake water due to potential hardness and organic content issues for PCB boards.