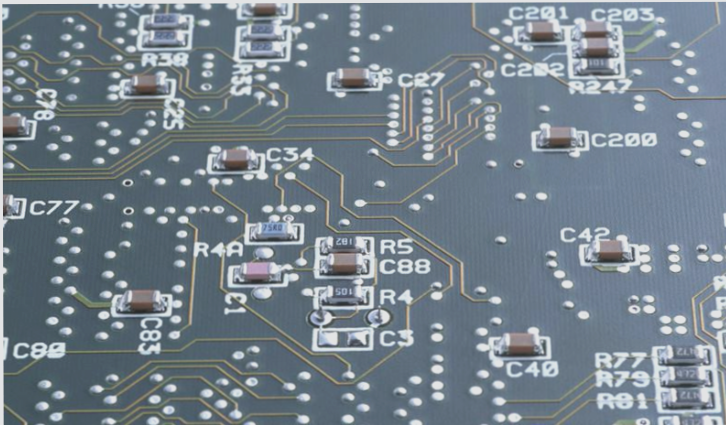

**PCB Ink Characteristics and Their Impact on Manufacturing**

PCB ink is a critical material in the production of Printed Circuit Boards (PCBs), where its physical properties—viscosity, thixotropy, and fineness—play a vital role in the manufacturing process. Understanding these properties is essential to optimizing ink performance and ensuring high-quality results in PCB production.

### 1. Viscosity and Thixotropy

In PCB manufacturing, screen printing is an essential step for precise image reproduction. To achieve high-quality prints, the ink must exhibit appropriate viscosity and thixotropy. Viscosity refers to the internal friction within a liquid, which affects how easily one layer of liquid can slide over another when subjected to external force. Thicker liquids have higher viscosity, meaning they resist flow more than thinner liquids. The unit of viscosity is measured in poise, and it is crucial to note that temperature can significantly affect viscosity. As temperature increases, the viscosity of ink generally decreases, making it easier to work with at higher temperatures.

Thixotropy is another important characteristic of PCB ink. This refers to the ability of a liquid to undergo a temporary reduction in viscosity when agitated, and then quickly recover its original consistency once agitation stops. This property is particularly beneficial in screen printing, as the ink needs to be both fluid for easy flow through the screen mesh and viscous enough to maintain its print quality when not in motion. During the screen printing process, the ink is stirred by the squeegee, reducing its viscosity, which facilitates its movement through the mesh. Once the squeegee ceases motion, the ink quickly regains its initial viscosity, ensuring that it remains in the correct form to maintain high fidelity in the printed design.

In summary, understanding and controlling the viscosity and thixotropy of PCB ink are crucial for achieving optimal print quality. These properties must be carefully balanced to ensure that the ink flows smoothly during screen printing while also maintaining the required viscosity for accurate and consistent results.

**Accuracy and Best Practices for PCB Ink Usage**

Pigments and mineral fillers, commonly used in PCB inks, are generally solid materials that undergo fine grinding. After grinding, their particle size does not exceed 4 to 5 microns, forming a homogeneous fluid state in a solid form. Given this, ensuring the right ink fineness is critical for achieving optimal results. Below are some essential guidelines and best practices based on the collective experience of PCB manufacturers for using PCB inks effectively:

### 1. Temperature Control

It is crucial to maintain the ink temperature between **20°C and 25°C**. Fluctuations outside this range can significantly affect ink viscosity, which in turn impacts both the quality and effectiveness of screen printing. If the ink is stored in varying temperature conditions, especially outdoors or in areas with high temperature differences, allow the ink to stabilize at room temperature before use. This ensures the ink reaches the appropriate operating temperature, preventing printing failures caused by cold ink. To preserve ink quality, it’s advisable to store the ink at room temperature or in controlled conditions that reflect the typical operating environment.

### 2. Proper Mixing and Handling

Before use, **thoroughly mix** the ink, either manually or with a mechanical stirrer, to ensure uniform consistency. Air bubbles in the ink should be allowed to dissipate by letting the mixture rest for a while. If dilution is required, mix the ink thoroughly first, then check its viscosity to ensure it is within the recommended range. After use, always **seal the ink tank** to prevent contamination. Never return ink used for screen printing back into the original ink container, as it may alter the quality of the remaining ink.

### 3. Cleaning the Equipment

To maintain the quality of the printing process, always use **compatible cleaning agents** for cleaning the screen mesh. The cleaning should be thorough to avoid contamination of the ink. When performing a secondary cleaning, it is important to use a **clean solvent** to ensure no residue remains that could interfere with subsequent printing.

### 4. Ink Drying Process

Proper drying is essential for achieving high-quality results. Ensure that the ink is dried in a **well-ventilated environment** equipped with a good exhaust system. This helps remove excess solvents and prevents issues such as improper curing, which can affect the integrity of the printed circuit.

### 5. Optimal Operating Conditions

Screen printing should always be performed in an environment that meets the technical requirements of the PCB manufacturing process. The workspace should be designed to maintain stable conditions that facilitate smooth and efficient ink application, ensuring consistent quality across all printed boards.

By adhering to these guidelines, manufacturers can maintain the accuracy, consistency, and reliability of PCB inks, thereby ensuring high-quality prints and reducing production-related issues.

PCB ink is a critical material in the production of Printed Circuit Boards (PCBs), where its physical properties—viscosity, thixotropy, and fineness—play a vital role in the manufacturing process. Understanding these properties is essential to optimizing ink performance and ensuring high-quality results in PCB production.

### 1. Viscosity and Thixotropy

In PCB manufacturing, screen printing is an essential step for precise image reproduction. To achieve high-quality prints, the ink must exhibit appropriate viscosity and thixotropy. Viscosity refers to the internal friction within a liquid, which affects how easily one layer of liquid can slide over another when subjected to external force. Thicker liquids have higher viscosity, meaning they resist flow more than thinner liquids. The unit of viscosity is measured in poise, and it is crucial to note that temperature can significantly affect viscosity. As temperature increases, the viscosity of ink generally decreases, making it easier to work with at higher temperatures.

Thixotropy is another important characteristic of PCB ink. This refers to the ability of a liquid to undergo a temporary reduction in viscosity when agitated, and then quickly recover its original consistency once agitation stops. This property is particularly beneficial in screen printing, as the ink needs to be both fluid for easy flow through the screen mesh and viscous enough to maintain its print quality when not in motion. During the screen printing process, the ink is stirred by the squeegee, reducing its viscosity, which facilitates its movement through the mesh. Once the squeegee ceases motion, the ink quickly regains its initial viscosity, ensuring that it remains in the correct form to maintain high fidelity in the printed design.

In summary, understanding and controlling the viscosity and thixotropy of PCB ink are crucial for achieving optimal print quality. These properties must be carefully balanced to ensure that the ink flows smoothly during screen printing while also maintaining the required viscosity for accurate and consistent results.

**Accuracy and Best Practices for PCB Ink Usage**

Pigments and mineral fillers, commonly used in PCB inks, are generally solid materials that undergo fine grinding. After grinding, their particle size does not exceed 4 to 5 microns, forming a homogeneous fluid state in a solid form. Given this, ensuring the right ink fineness is critical for achieving optimal results. Below are some essential guidelines and best practices based on the collective experience of PCB manufacturers for using PCB inks effectively:

### 1. Temperature Control

It is crucial to maintain the ink temperature between **20°C and 25°C**. Fluctuations outside this range can significantly affect ink viscosity, which in turn impacts both the quality and effectiveness of screen printing. If the ink is stored in varying temperature conditions, especially outdoors or in areas with high temperature differences, allow the ink to stabilize at room temperature before use. This ensures the ink reaches the appropriate operating temperature, preventing printing failures caused by cold ink. To preserve ink quality, it’s advisable to store the ink at room temperature or in controlled conditions that reflect the typical operating environment.

### 2. Proper Mixing and Handling

Before use, **thoroughly mix** the ink, either manually or with a mechanical stirrer, to ensure uniform consistency. Air bubbles in the ink should be allowed to dissipate by letting the mixture rest for a while. If dilution is required, mix the ink thoroughly first, then check its viscosity to ensure it is within the recommended range. After use, always **seal the ink tank** to prevent contamination. Never return ink used for screen printing back into the original ink container, as it may alter the quality of the remaining ink.

### 3. Cleaning the Equipment

To maintain the quality of the printing process, always use **compatible cleaning agents** for cleaning the screen mesh. The cleaning should be thorough to avoid contamination of the ink. When performing a secondary cleaning, it is important to use a **clean solvent** to ensure no residue remains that could interfere with subsequent printing.

### 4. Ink Drying Process

Proper drying is essential for achieving high-quality results. Ensure that the ink is dried in a **well-ventilated environment** equipped with a good exhaust system. This helps remove excess solvents and prevents issues such as improper curing, which can affect the integrity of the printed circuit.

### 5. Optimal Operating Conditions

Screen printing should always be performed in an environment that meets the technical requirements of the PCB manufacturing process. The workspace should be designed to maintain stable conditions that facilitate smooth and efficient ink application, ensuring consistent quality across all printed boards.

By adhering to these guidelines, manufacturers can maintain the accuracy, consistency, and reliability of PCB inks, thereby ensuring high-quality prints and reducing production-related issues.