Two-stage hot-baking hardening type plug ink, its hardening process can be divided into two stages, the first stage of hardening is pre-baking, and the degree of ink hardening after pre-baking is usually 4-5H. Grinding can also reduce grinding costs. After grinding is completed, the second stage of hardening is performed, which is called post-curing. After the second stage of baking, the ink can harden up to 8-9H. Although two-stage baking takes more time, the overall efficiency (especially the plugging quality and brushing benefit) is better than that of one-stage hot-baking hardening plugging ink. The Noda plugging process is the most famous user of UV exposure heat-bake-hardening plugging ink. The process is similar to the two-stage heat-baking-hardening plugging ink, except that the first-stage curing Pre-Curing uses the low-temperature liquid exposure machine successfully developed by Noda Company is exposed and hardened in the low-temperature liquid environment. The hardness after hardening is about 2-3H, and then the brushing and post-baking operations are performed. The company’s exclusive technology and the limited information disclosed cannot be described here.

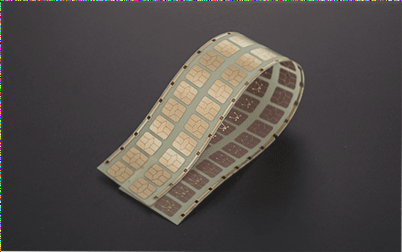

At present, most of the inner layer plugging inks on the market have been changed to solvent-free formulations regardless of the hardening type. The solvent will be volatilized by heat during the baking process, but if the plug hole diameter is high in aspect ratio, it will be relatively difficult for the solvent to be completely discharged. Some of the solvents will remain in the hole, and the residual solvent will expand again during the heating process, possibly causing cracks in the ink. Especially when the high-temperature and short-time baking method is combined with the high aspect ratio pore size, it is easy to produce a skinning effect where the ink at the orifice has hardened but the ink inside the pore size is not completely hardened, making it easier for the solvent to remain in the hole, causing poor plugging. Low-temperature and long-term baking can help the discharge of volatile components in the ink. 100% solid content and solvent-free plugging ink can reduce the expansion and hardening of residual solvent, minimizing post-ink shrinkage.

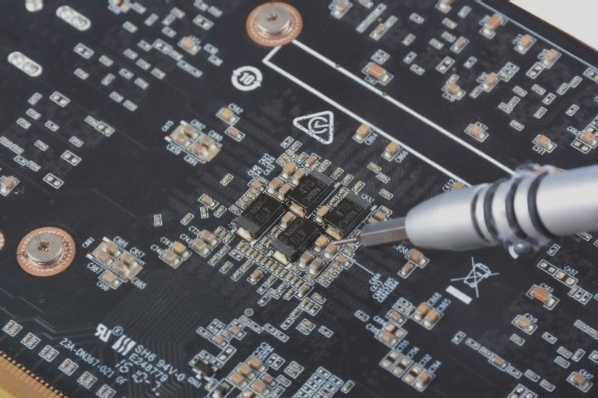

To ensure the quality of inner plug hole grinding and avoid abnormal grinding caused by improper equipment and conditions, it is necessary to focus on hole depression, hole angle damage, sheet expansion and shrinkage, grinding roughness, grinding amount, and various other characteristics such as grinding cost, sheet capacity, and grinding wheel matching. The equipment commonly used in the inner plug hole grinding process includes:

(1) Belt Sander.

(2) Automatic pressure regulating grinder.

The grinding wheels used in the automatic pressure regulating type grinding machine include ceramic grinding wheels and non-woven grinding wheels. Ceramic grinding wheels have better cutting ability and leave no dents on the surface after grinding, but they are expensive and have a short service life. Non-woven grinding wheels also have excellent cutting ability but are more likely to leave hole depressions due to their structure. Manufacturers can choose grinding wheels based on individual plugging characteristics and cost considerations. In terms of expansion and shrinkage control, after testing with four-axis grinding, rotating the inner layer plate 90° and then performing post-four-axis grinding can achieve the best grinding roughness and expansion and shrinkage control, distributing damage to the orifice and avoiding concentration in a single direction.

At this stage, the inner layer plugging process has various suppliers offering options for equipment, raw materials, and grinding methods. The industry can find the most suitable equipment, materials, and optimized production conditions according to actual needs to carry out the inner layer plugging operation.

At present, most of the inner layer plugging inks on the market have been changed to solvent-free formulations regardless of the hardening type. The solvent will be volatilized by heat during the baking process, but if the plug hole diameter is high in aspect ratio, it will be relatively difficult for the solvent to be completely discharged. Some of the solvents will remain in the hole, and the residual solvent will expand again during the heating process, possibly causing cracks in the ink. Especially when the high-temperature and short-time baking method is combined with the high aspect ratio pore size, it is easy to produce a skinning effect where the ink at the orifice has hardened but the ink inside the pore size is not completely hardened, making it easier for the solvent to remain in the hole, causing poor plugging. Low-temperature and long-term baking can help the discharge of volatile components in the ink. 100% solid content and solvent-free plugging ink can reduce the expansion and hardening of residual solvent, minimizing post-ink shrinkage.

To ensure the quality of inner plug hole grinding and avoid abnormal grinding caused by improper equipment and conditions, it is necessary to focus on hole depression, hole angle damage, sheet expansion and shrinkage, grinding roughness, grinding amount, and various other characteristics such as grinding cost, sheet capacity, and grinding wheel matching. The equipment commonly used in the inner plug hole grinding process includes:

(1) Belt Sander.

(2) Automatic pressure regulating grinder.

The grinding wheels used in the automatic pressure regulating type grinding machine include ceramic grinding wheels and non-woven grinding wheels. Ceramic grinding wheels have better cutting ability and leave no dents on the surface after grinding, but they are expensive and have a short service life. Non-woven grinding wheels also have excellent cutting ability but are more likely to leave hole depressions due to their structure. Manufacturers can choose grinding wheels based on individual plugging characteristics and cost considerations. In terms of expansion and shrinkage control, after testing with four-axis grinding, rotating the inner layer plate 90° and then performing post-four-axis grinding can achieve the best grinding roughness and expansion and shrinkage control, distributing damage to the orifice and avoiding concentration in a single direction.

At this stage, the inner layer plugging process has various suppliers offering options for equipment, raw materials, and grinding methods. The industry can find the most suitable equipment, materials, and optimized production conditions according to actual needs to carry out the inner layer plugging operation.