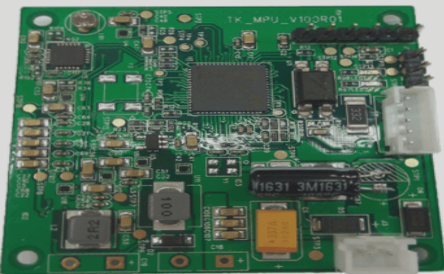

Understanding the Difference Between VIA and PAD in PCB Design

The Challenge of Non-Standard Designs

One of the recurring issues in PCB circuit board design is the confusion between “via cap oil” and “via opening window” when placing orders. This confusion often arises due to the lack of standardization in PCB designs, making it challenging to differentiate between pads and vias.

The Importance of PAD and VIA Attributes

To address this issue, it is crucial to understand the distinct attributes of pads and vias. A pad serves as a copper surface for soldering components, while a via is a hole that connects different PCB layers. Misusing these attributes can lead to manufacturing errors and significant delays.

The Impact on Production

Non-standardized PCB designs can complicate the CAM data handling process for manufacturing plants. CAM engineers may need to make manual adjustments to correct VIA and PAD attribute inconsistencies, potentially causing delays and errors throughout production stages.

Best Practices for Clarity

To avoid confusion and streamline the PCB production process, designers should adhere to standardized practices when defining VIA and PAD attributes. Clear documentation, adherence to design guidelines, and thorough review of design files before ordering can help minimize errors and improve efficiency.

Additional Resource: PCB Design and File Preparation Best Practices

Learn more about best practices for preparing PCB design files, including tips on conductive holes, keyholes, and file integrity. Following design standards and specifications, focusing on key design elements, and avoiding common mixing issues with pads and vias are essential for successful PCB manufacturing.

Common Issues in PCB Design: Vias, Pads, and Cover Oil

One of the most common problems in PCB design arises when pads and vias are mistakenly interchanged. This can lead to complications during the application of solder mask or cover oil on vias.

Key Tip: Verify Pad and Via Attributes

When dealing with pads or Protel files, always double-check to ensure that via holes are not mistakenly marked as pads or vice versa. This simple precaution can prevent significant issues down the line.

Via Cover Oil Disputes

Another issue occurs when via holes that require cover oil are incorrectly designated as pads in the design files. This can result in poor solderability and disputes with customers regarding the application of cover oil.

Protel and PADS Considerations

Understanding the distinct functions of vias and pads in Protel or PADS is crucial. Vias establish electrical connections between PCB layers, while pads are essential for component leads. Confusing these components can lead to manufacturing errors.

Gerber Files and Solder Mask Layers

Discrepancies in Gerber files, especially in the solder mask layer, can cause confusion during manufacturing. Properly defining solder mask layers ensures that vias are appropriately capped or exposed based on design requirements.

File Conversion and Standard Practices

When converting files between Protel, PADS, and Gerber formats, clarity in representing vias and pads is paramount. Failure to distinguish between vias and keyholes in Gerber files can lead to production delays and faults.

Conclusion: Embrace Standardized Practices

Designing with clarity and adhering to industry standards is crucial in PCB design. By following best practices and ensuring clear file indications, you can streamline the manufacturing process and enhance product quality.

Remember, precision in via design and proper treatment of pads are key to achieving efficient manufacturing processes and superior product outcomes.

Expert PCB Advice Available

For any inquiries regarding PCB or PCBA, don’t hesitate to contact me via email at info@wellcircuits.com.

Latest PCB Trends

- 1. The demand for flexible PCBs is on the rise due to their versatility and space-saving benefits.

- 2. PCB designers are increasingly focusing on high-speed and high-frequency PCB designs to meet the requirements of advanced technologies.

- 3. The integration of IoT devices is driving the development of smaller and more efficient PCBs.

Feel free to contact me for more insights and guidance on navigating the dynamic world of PCB technology.