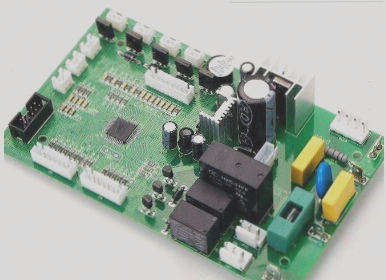

In the field of electronic manufacturing, two primary automated soldering techniques are widely used for assembling printed circuit boards: reflow soldering and wave soldering. These two methods have distinct principles and applications, and their use cases vary depending on the specific requirements. In this article, we will provide an overview of these two techniques, highlight their similarities and differences, and discuss how the electronics industry decides which soldering technique to employ in different scenarios.

What is Reflow Soldering?

Reflow soldering is a process where pre-applied solder paste on the solder pads is heated until it melts, allowing the leads or pins of electronic components to form electrical connections with the PCB, effectively soldering the components onto the board. Reflow soldering uses hot air or other heat sources to induce a physical reaction in the solder paste, causing it to flow and form strong solder joints, which is why it is called “reflow soldering.” Typically, the reflow soldering process consists of preheating, heating, and cooling stages within the soldering machine, where hot gases circulate to generate the necessary high temperatures.

Reflow Soldering Process

The process begins by accurately applying solder paste to the PCB using a stencil. Then, components are placed on the pads using a specialized tool called a “pick and place” machine. The reflow soldering process follows these steps:

Preheating: In this stage, the PCB is gradually heated according to a specific thermal profile to remove any volatile solvents present in the solder paste.

Thermal Soak: After preheating, the board enters the thermal soak zone. Here, it is held at a consistent temperature for two main reasons: to ensure areas that may have been shadowed during preheating reach the necessary temperature, and to activate the flux and evaporate the remaining solvents from the solder paste.

Reflow Soldering: The reflow zone is where the solder reaches its peak temperature and melts, creating solder joints between the component leads and the PCB. In this stage, the flux reduces surface tension, facilitating metallurgical bonding between the components and the PCB. This process allows the individual solder powder spheres to combine and melt into solid joints.

Cooling: After reflow, the board is cooled in a controlled manner to prevent any stress to the components. Proper cooling helps prevent the formation of excessive intermetallic compounds and thermal shock. The typical cooling temperature range is between 30-100°C (86-212°F), where a relatively fast cooling rate ensures the best mechanical properties and grain structure in the solder joints.

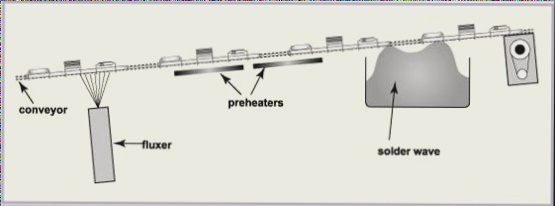

What is Wave Soldering?

Wave soldering is a process in which molten solder (usually a lead-tin alloy) is pumped or jetted into a wave-like shape. Pre-assembled printed circuit boards, with components already placed, pass through this solder wave to achieve both electrical and mechanical connections between the component leads and the PCB solder pads. A wave soldering machine generally consists of a conveyor belt, flux application area, preheating zone, and a solder wave bath. The primary material used in wave soldering is solder bars.

Wave Soldering Process

The wave soldering process consists of four key stages:

Flux Spraying: Flux is applied to the PCB to remove oxide layers and improve solderability. It lowers surface tension, enhances heat transfer, and ensures a smoother soldering process.

Preheating: The PCB is heated in a tunnel, preparing the board for soldering. This helps activate the flux and ensures uniform heating across the board.

Wave Soldering: The molten solder forms a wave, and as the board passes through, the component leads are immersed in the wave, forming strong solder joints between the leads and the PCB pads.

Cooling: After the soldering process, the PCB is cooled to a safe temperature, allowing the solder joints to solidify. Cooling ensures the components and solder joints are properly set for the next stages of assembly.

During wave soldering, several factors—such as temperature, wave contact time, and conveyor belt speed—play a crucial role in determining the quality of the soldering process. These variables should be carefully controlled for optimal results.

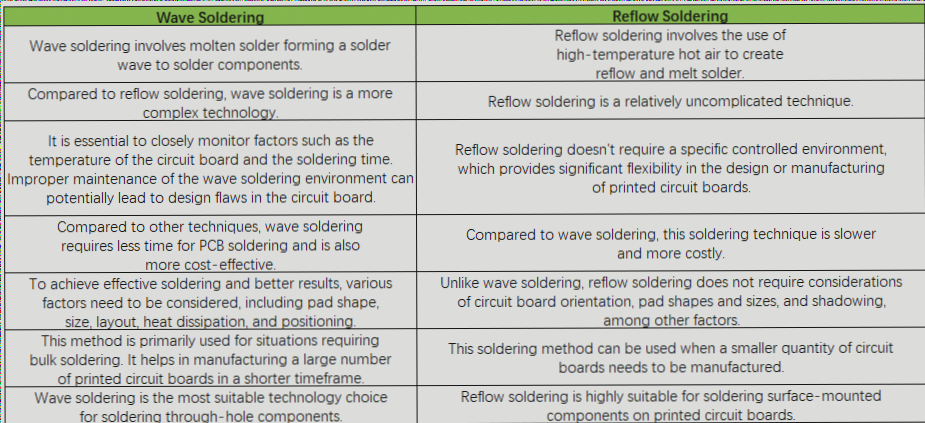

Differences Between Reflow Soldering and Wave Soldering

If you have any questions regarding PCBs and PCBA, feel free to contact us at info@wellcircuits.com.