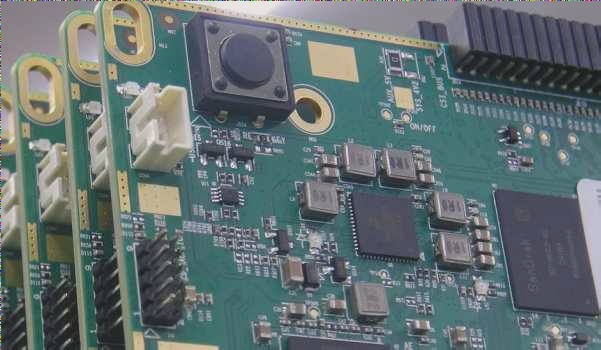

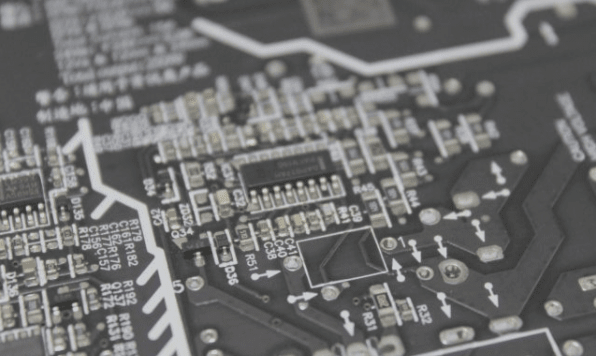

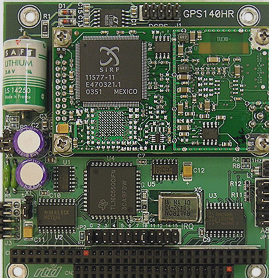

Surface Mount Technology (SMT) vs. Through-Hole Technology in PCB Assembly

- Most SMT chip components are reflow soldered, while through-hole components are wave soldered, though exceptions exist.

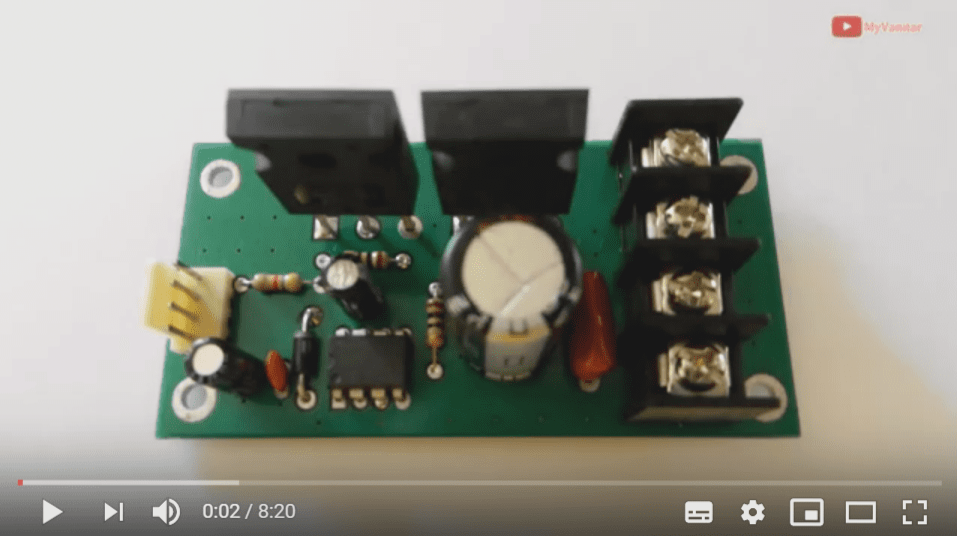

- In through-hole PCB assembly, components are manually inserted and wave soldered to form strong joints.

- For SMT components, solder paste is applied to pads, holding component leads in place.

- Reflow ovens are used in SMT assembly to create solid solder joints.

- Hybrid PCBs may require both wave and reflow soldering methods.

- Automatic pick-and-place machines are available for component handling.

The Advantages of SMT and Through-Hole Technologies

- SMT Benefits:

- 1. Size: SMT components are small, eliminating the need for drilling and providing a clean look suitable for compact electronics.

- 2. Availability: SMT components are increasingly replacing through-hole parts in PCBA assembly.

- 3. Performance: SMD integration in SMT allows for shorter signal paths, reducing signal flight time.

- 4. Cost-effectiveness: SMT parts are often more affordable compared to through-hole components.

- Through-Hole Advantages:

- 1. Availability: Larger through-hole components are easier to source for high-power applications.

- 2. Strength: Through-hole solder joints offer robustness, ideal for connectors and switches under pressure.

- 3. Power: Through-hole technology provides better mechanical strength for high-power circuits.